Filtration

Inputs/Production

Product information

Donaldson Torit

– material handling solutions

TARYN TERNENT, PUBLIC RELATIONS OFFICER, DONALDSON FILTRATION

SYSTEMS

Dust control in grain operations can present challenges to material

handling operations, but Torit® PowerCore® CPV bin vent collectors

helps to ensure optimised material handling by providing effective and

efficient filtration.

To optimise throughput while maintaining effective dust collection

performance, proactive collaboration is needed between the elevator

operator, the general contractor and the dust collector manufacturer.

Elevator operators who proactively and

thoughtfully design point-of-use dust

collection, typically realise the following

benefits:

Faster material transfer

The Torit PowerCore CPV collector

effectively captures dust while avoiding

whole grain being pulled from material

transfer points. Operators do not have

to constantly adjust damper positions to

maintain the material handling system’s

effectiveness even at full dumping rates.

With the use of optional items, such

as a variable frequency drive and

downtime filter cleaning, the limit on

the receiving rate will be based solely

on the conveying equipment – not on

the ability to control dust. The result is

increased throughput from the elevator.

Smaller collectors

Torit PowerCore CPV bin vent collectors

are almost 70% shorter than other bag-

style bin vents and effectively address

the frequent challenge of tight space

limitations.

Easier maintenance

Clean-side filter access and fewer,

lighter filter packs mean faster, easier

filter changes without tools, filter cages

or confined space entry.

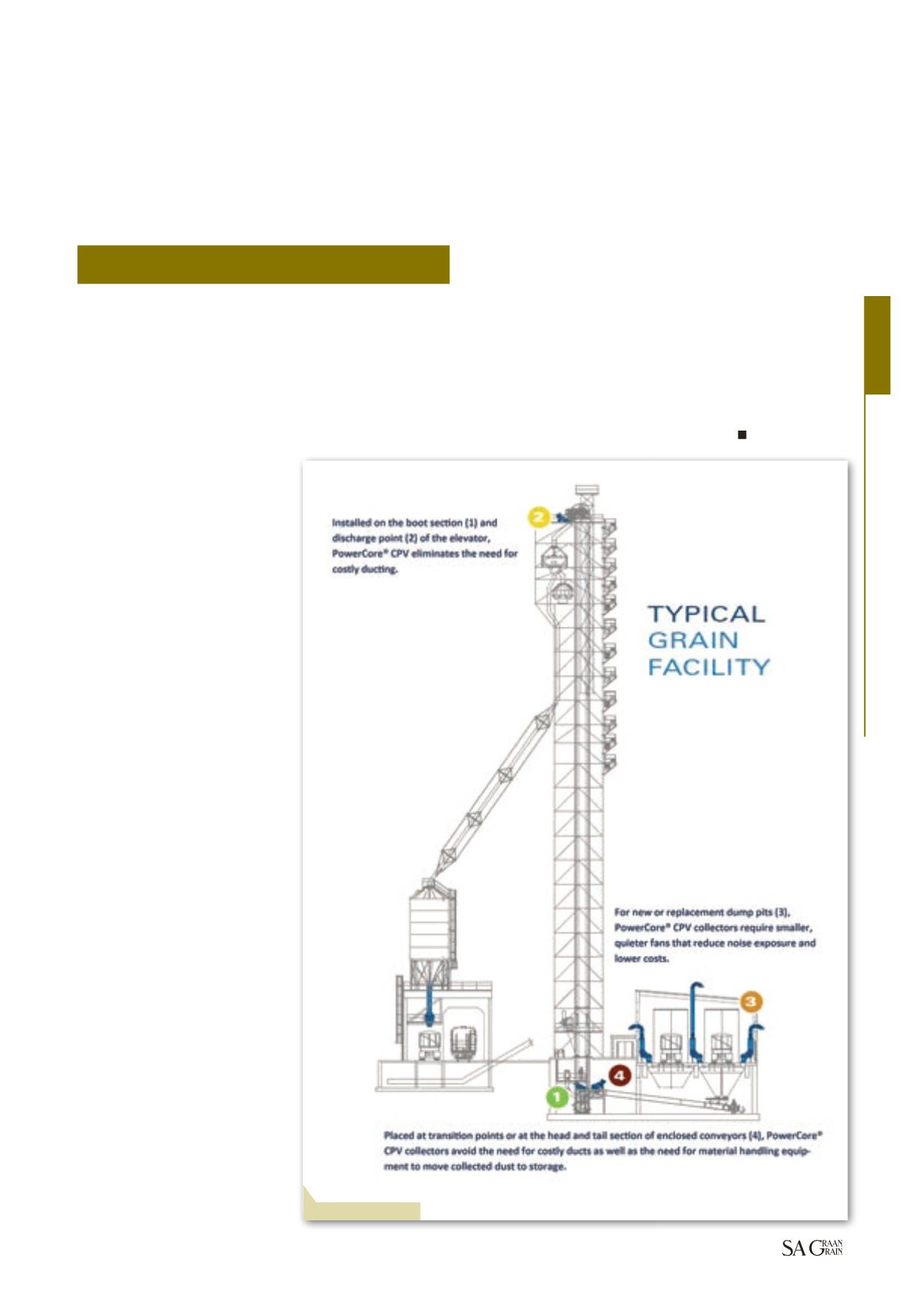

Less equipment

The collectors in point-of-use dust

collection, eliminate dirty-air ducting

while balancing gates, airlocks, fil-

ter hoppers, screw conveyors and

pneumatic conveying equipment other-

wise needed to move collected dust to

storage bins. Effective point-of-use dust

collection will reduce the installation

and the maintenance cost of your dust

control.

Lower energy consumption

An optimised pulse system delivers effective cleaning while minimising

restriction through the collector for filtered air. As a result, the collectors

require up to 40% less horsepower to operate compared to traditional

bag-style collectors. The resulting energy savings alone may actually pay

for the integrated system over the lifespan of the equipment.

Cost-effective

PowerCore filtration technology means reduced freight and installation

costs, fewer filter change-outs, lower maintenance costs, reduced emis-

sions and, therefore, reduced housekeeping costs.

57

October 2013

A typical grain facility.