B

ased in Durban, home to the busi

est port in the country on the East

Coast of South Africa, Bagtech In

ternational is truly a South African

company with a passion for Africa. At the

helm of it is Mr Fred Coelho (managing di

rector) who is at the centre of every project

undertaken.

Bagtech is in the unique position of run

ning the equipment it manufactures and

sells. We currently bag and blend more than

400 000 tons per annum for ten plus clients

at various operational sites including Om

nia, Yara, Gavilon and others around South

Africa. It is this mix of business that allows

us to understand clients’ needs and that

has made us an efficient warehouse man

agement company.

It is this background that has led to the

company being a leader in fertiliser equip

ment in Africa with more than 90 successful

projects delivered until now. We consider

ourselves an African company and provide

custom made equipment for Africa. Over

the past 24 months we have delivered, in

stalled and commissioned equipment for

over six countries in Africa.

One of our clients is Toyota Kenya, who

encouraged and trusted our AI technology

and experienced team to design the pro

ject of the first fertiliser blending plant for

Kenya. The plant was designed and built

according to Toyota’s safety standards.

This machine can blend, add micronutri

ents, screen the dust, and coat and then

bag the fertiliser. The capacity of the plant

reaches 50 tons/hour, bagging 18 bags/

minute. The bagging machine can bag from

10 kg to 50 kg bags.

Toyota Kenya

‘The fertiliser market of every country has

different requirements to others and we are

prepared to design according to a custom

er’s needs in any market. We are not only a

supplier; we want to bring solutions to our

customers to develop Africa,’ said Coelho.

Manufacturing from our workshop based

in the harbour complex, our machines are

designed after extensive interaction with

the client whereby we are involved in all

aspects from the warehouse design to the

warehouse layout.

All machines are made from 304 stain

less steel and we are able to manufacture

machines with capacities ranging from

40 tons/hour through to 75+ tons/hour. A

smart system with integrated artificial intel

ligence controls all aspects of the process

and allows for the memory of flow rates

which leads to efficient time management.

Our efficiency is carried forward to the ac

curacy of our machines; any improvement

in accuracy no matter how small, will lead

to savings for our clients. Our team consist

ently works on improving the speed, accu

racy and efficiency of our machines for the

client’s benefit.

Machines are transported in four to five

40-foot-high cube containers and shipped

to the client’s operation where it is in

stalled by a team of technicians supplied

by Bagtech. Upon commissioning we hand

over to the client, but not before having pro

vided on the job training for their employees

allocated to run the machine.

Online system support is a much-appreciat

ed aspect of our equipment. For the client’s

benefit, peace of mind as well as to curb

cost, Bagtech is able to access the client’s

machines from anywhere in the world and

attempt to solve any issues online before

sending a technician. This ensures less

down time and less cost for the client.

No matter where you are, our team will pro

vide a solution to your warehousing and

equipment needs. Bagtech is your partner

in the agribusiness industry.

Your fertiliser warehouse

and equipment partner in Africa

Product information

Dave Payne,

finance manager, Bagtech and

Larissa G Zerbatto,

marketing manager, Bagtech International

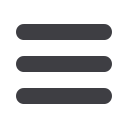

1: Bagtech fertiliser machine and warehousing management service in South Africa.

2: Toyota’s management visited Bagtech's workshop.

2

1

Scan this QR code or visit

https://www.youtube.com/

watch?v=fI9VE7YrkvU&t=47s

for

more information on the Toyota

Kenya NPK fertiliser blending plant.

Fokus

Bemesting

51

July 2018