www.nampo.co.za

www.nampo.co.za

50

Graan|Grain

M

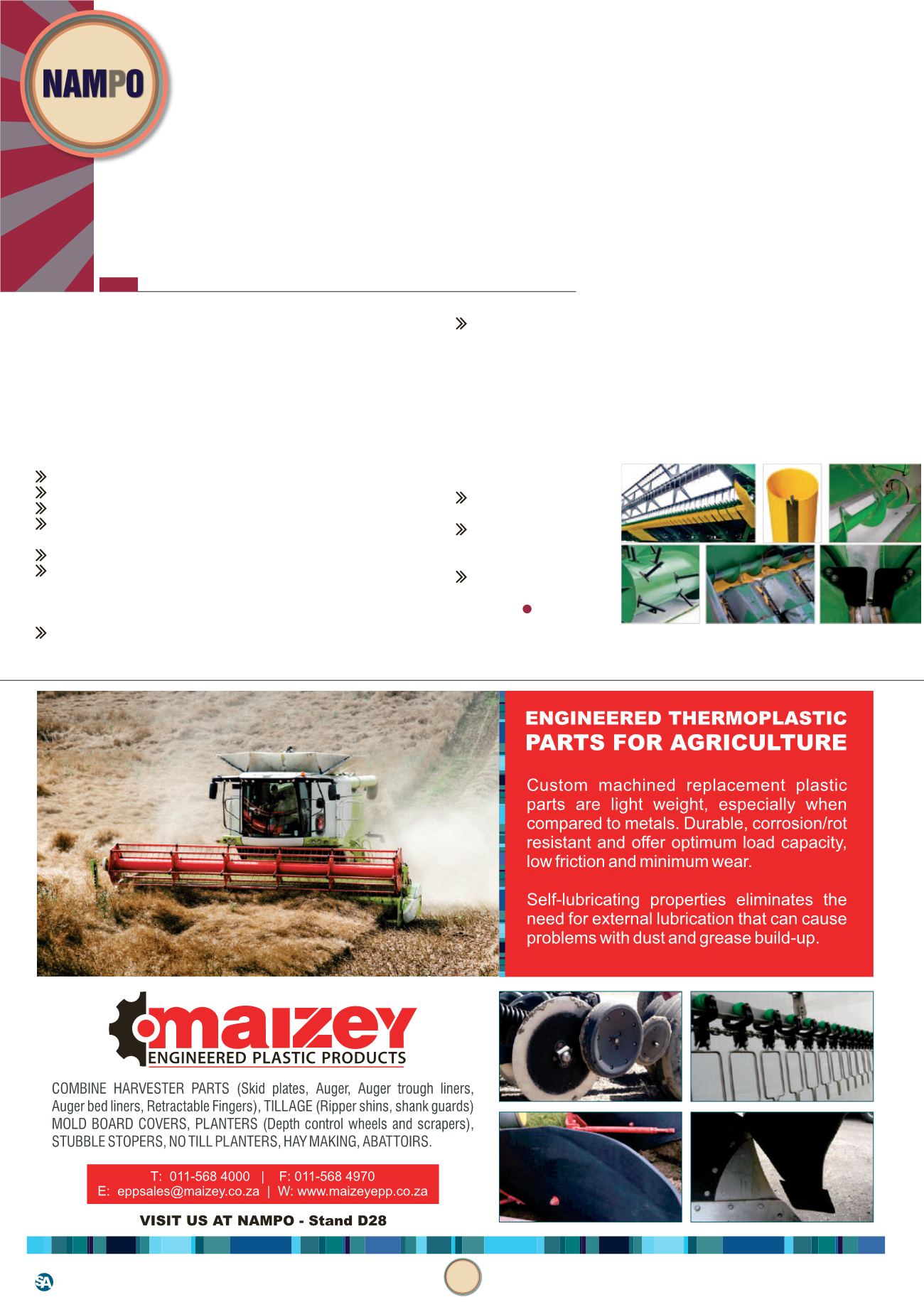

odern farming equipment represents a huge invest-

ment. Replacement parts that can withstand the

harsh demands of agricultural applications and

reduce costs, have resulted in an increased use of

engineering thermoplastics. Thermoplastics are

tough, durable and lightweight and the increase in

service life make them a perfect alternative to traditional construc-

tion materials.

Advantages of thermoplastic parts

Lightweight, especially when compared to metals.

Durable and corrosion resistant.

Optimum load capacity with minimum wear.

Low friction and low wear – increase part life and result in less

down time, thus increasing efficiencies.

Cost effective – overall very economical to produce.

Self-lubricating properties. This also saves costs by eliminating the

use of lubrication fluids. External lubrication can also cause prob-

lems with dust and grease build-up and leach into the surround-

ing soil and water.

Resistant to environmental decay – will not rot, swell, splinter or

degrade.

Very little soil adherence compared to metal counterpart – less

weight and carry-back.

We as Maizey Engineering Plastics are specialists in our field. We of-

fer high levels of material selection advice and application devel-

opment support across a wide range of industries with extensive

solutions already developed to support the agricultural industry. A

widespread distribution footprint in Southern Africa ensures product

availability, whilst high levels of technical expertise mean we excel in

delivering innovative applications.

Key focus areas

Semi-finished materi-

als distribution.

Applications devel-

opment, support and

CAD/CAM design.

Custom machining

and industrial fabri-

cation.

Kevin Govender,

chief sales officer, Maizey Engineering Plastics

Engineering

thermoplastics perform

Replacement parts reduce cost and

improve efficiencies.

NAMPO-SA GRAIN_print

19 March 2019 07:15:55 PM

P

2019

Product

information