75

September 2018

10 000 kl’s of liquid insecticides were pro

duced exclusively for crop protection, of

which 43% consisted of highly toxic organo

phosphates.

Bio-insecticides of botanical origin have

gained a great deal of interest, also being

in direct support of organic agriculture. As

pointed out in a recent review paper by Is

man (2015), ‘

…globally, bio-pesticides could

hold close to 20% of the pesticide market by

2025 and botanicals up to 7% of the mar-

ket, based on 15% to 20% annual growth in

sales

’ (see

Pest Management Science

2015;

71:1 587 - 1 590).

An important group of botanical insecti

cides is the so-called pyrethrums, made

from the flowers, of mainly, the Dalmatian

chrysanthemum,

Tanacetum cinerariifolium

(Asteraceae) (

Photo 2

). The derived insec

ticide (pyrethrin) is a mixture of six active

components (pyrethrins I and II, cinerins I

and II, and jasmolins I and II). Pyrethrum is

the main botanical in use, capturing nearly

80% of the global botanical insecticide mar

ket and has been used for insect control for

over 150 years.

Previously, the notion of integrating en

tomopathogenic fungi with chemical in

secticides was discussed by the same

authors of this article, in the September

2015 issue of

SA Graan/Grain

(page 42).

However, although such combinations do

show potential, expanded benefits can be

derived through the combination of an en

tomopathogenic fungus with botanicals,

creating a purely organic alternative.

In the USA, the product BotaniGard

®

MAXX,

is one such product, formulated with

B. bassiana

strain GHA (0,06%) combined

with pyrethrins (0,75%). However, research

with an indigenous strain of this fungus

was needed and subsequently initiated by

ARC-Small Grain as part of an MSc study by

the author, Nokulunga Mzimela.

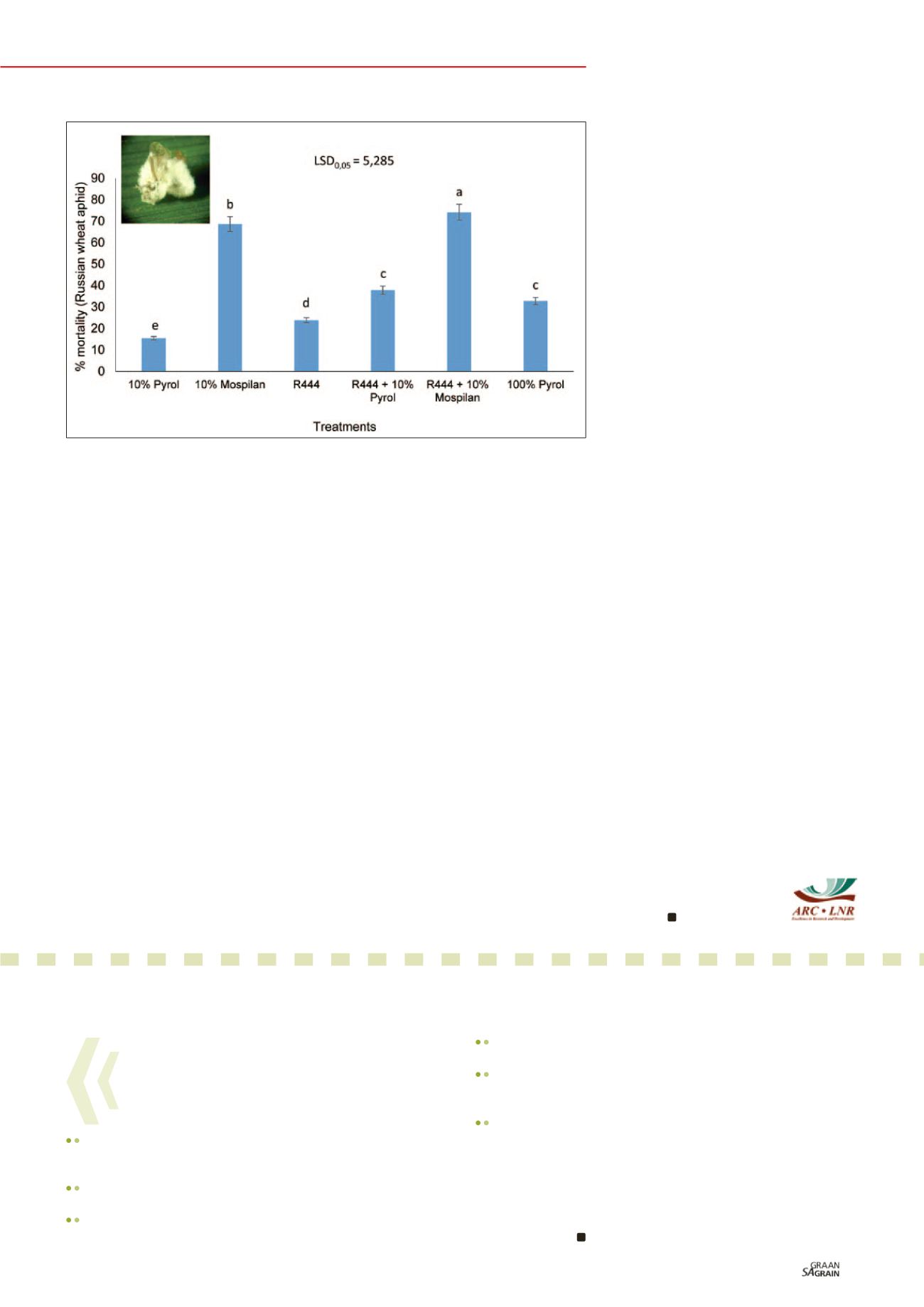

Laboratory experiments showed compat

ibility between

B. bassiana

strain R444 and

various concentrations of the pyrethrum-

based insecticide, Pyrol

TM

, a certified or

ganic insecticide registered under Act 36

of 1947 (L7062), with active ingredients:

Canola oil 89,5% and pyrethrins 0,5%. Inter

estingly, at a reduced concentration of 10%,

Pyrol increased the sporulation intensity of

the fungus and the combination was then

further tested against the Russian wheat

aphid, together with a chemical (Mospilan

®

),

under glasshouse conditions. Mortality re

sults are visually presented in

Graph 1

.

A synergistic effect was noted with

B. bassi-

ana

R444 + 10% Pyrol, yielding a statisti

cally similar level of control compared with

the (full-dose) of Pyrol, alone. Likewise,

when comparing the

B. bassiana

R444 +

10% Pyrol treatment to the solo 10% Pyrol

treatment, efficacy was more than doubled.

These results demonstrate good compat

ibility between the fungus and this botani

cal insecticide, with a clear additive effect

in terms of aphid mortality.

Although so far tested only against Russian

wheat aphid, such combinations may also

prove effective against other aphid species

like the oat aphid,

Rhopalosiphum padi

, an

important vector of barley yellow dwarf

virus in South Africa.

The notion of combining entomopatho

genic fungi with a chemical or botanical

insecticide as a ‘two-in-one’ tank mix, has

been successfully employed against vari

ous insect pests to reduce the selection

pressure brought about by the insecti

cide (some insects in a given population

inherently resistant or less susceptible)

and to avoid concurrent development of

resistance in target pests.

Other benefits relate to lower volumes of

chemical insecticides applied to the envi

ronment, less (human) exposure to harmful

chemicals, during and after

application, and lower or no

residues on harvested com

modities.

Graph 1: Mortality of Russian wheat aphid,

Diuraphis noxia

, exposed to unformulated

Beauveria

bassiana

strain R444, combined with a sub-lethal dose of pyrethrum and Mospilan insecticides, or

as solo products. Bars with different letters, differed significantly at the 5% test level.

Onderhoud

Sekerlik een van die maklikste en sekerste maniere om swak

spuitresultate te kry, is gesetel in iets so eenvoudig soos die korrekte

onderhoud van die spuitstelsel. Operateurshandleidings spel die

vereistes in fyn besonderhede uit en van die belangrikstes om in

gedagte te hou, is:

Spuitpunte moet weekliks getoets word om te bepaal of lewering

binne die spesifikasies is. Indien dit met meer as 10% van

leweringsnorm afwyk, moet dit vervang word.

Filters moet daagliks uitgehaal, skoongemaak en geïnspekteer

word.

Roerders moet ten minste met seisoenale onderhoud uitgehaal

en skoongemaak word.

Herkalibrasie van sensors op ‘n seisoenale basis kan groot foute

voorkom.

Skoonmaak – binne en buite – is die eenvoudigste en sekerste

manier om diensbaarheid en waarde te behou. Doen dit deeglik

en op ‘n weeklikse basis.

Volledige jaarlikse onderhoud moet direk na die spuitseisoen

gedoen word – en nie voor die volgende seisoen nie.

Voor aanvang van die nuwe spuitseisoen is dit noodsaaklik om tydig

weer die stelsels te toets en seker te maak dat alles in ‘n werkende

toestand is. Raadpleeg die volledige handleidings wat saam met die

toerusting aan jou voorsien is, ten einde die verskillende inspeksies

korrek uit te voer.

Hoe maak mens ‘n

sinvolle keuse

?