September 2018

100

Machinery and implements for

conventional farming systems

T

he optimal use of the correct equipment and implements is

necessary to optimise farming production and to maximise

operational profit. All mechanisation actions need to be con-

sidered for the whole conventional farming value chain.

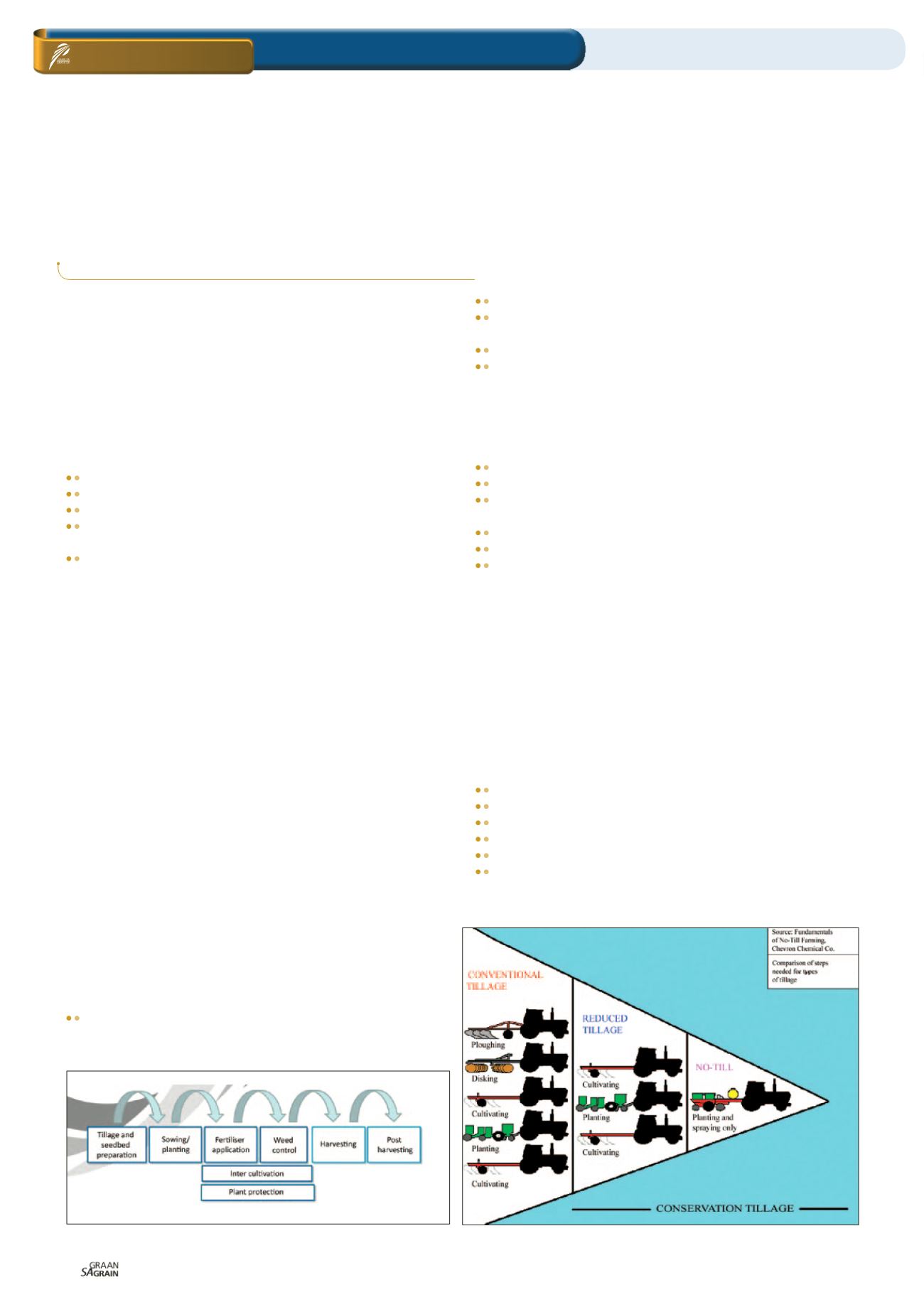

These actions are illustrated in

Figure 1

. Certain activities, like plant-

ing and harvesting, need to be done in a specific time window. There-

fore, mechanisation is necessary to adhere to the time limits set.

To mechanise farming activities, one needs to consider the following

factors:

Appropriate equipment to be used for timely crop production.

Manufacturing and availability of machine or implement parts.

Suitable capability and capacity for maintenance.

Effective utilisation and operation (skilled operators and techni-

cal staff must be available and affordable).

Favourable economic and financial conditions to support

mechanisation.

The planning and selection of tractors and implements for crop

production can greatly impact the performance and profitability of

the farming operation. The type and size of tractors and equipment

used, and matching of tractor engine power and capacity of imple-

ment can also influence energy efficiency.

During the peak period of the farming process, such as planting and

harvesting, time constraints are a great concern and enough tractors

and implements are necessary to complete the actions within the

specific time window. Too much surplus mechanisation capacity will

increase the operational cost and thus reduce the profitability.

Introduction to tractors

Tractors are the powerhouse for implements and are classified ac-

cording to their capacity (engine power in kW) and type. The trac-

tor type can be two-wheel driven, four-wheel driven or track laying

traction.

It is, however, important to utilise the tractor’s capacity in such a way

that the tractor-to-implement match is optimised for good traction

control and economic fuel consumption. It is also important to have

enough capacity to do the work on time without having surplus trac-

tors available when the operational time window is limited.

Function of a tractor

Providing draught power for tillage tools through the drawbar

or three point linked hitch system.

Used for trailing and transportation of farm products.

Power source – PTO, hydraulic and electrical output to drive

other machines.

Earth moving.

Transport.

Selection of farm tractors

It is important to select the appropriate size and numbers of farm

tractors according to the mechanisation plan. The following factors

can influence the tractor selection:

Farm area to be cultivated.

Type of crops to grow.

Mechanisation activities necessary for the various crops on the

farm.

Soil structure and condition of terrain.

Size of implements to be driven.

Financial capability.

Selection between 4x4 and 4x2 tractors

The 4x4 tractors have better traction performance than the 4x2s,

hence better drawbar pull performance under poor terrain condi-

tions. However, 4x4 tractors are more expensive (purchase and

maintenance). It is more economical to select 4x2s for light-duty op-

erations under better terrain conditions.

Selection of implements and farm

machinery

The selection of implements and machinery will be influenced by

the following factors:

The crop and production method: CA or conventional.

Implement performance.

Timeliness of operations.

Power availability.

Operation capacity.

Machinery selection will depend on the performance character-

istics, costs, and types of operation.

on farm level

Appropriate equipment / Implement performance

Implements and equipment

Johan van Biljon

and

Dr Tingmin Yu,

ARC-Agricultural Engineering

Figure 1: Mechanised solution for whole farming value chain.

Figure 2: Conservation tillage can be divided into reduced tillage and no-till.