FOCUS

Grain handling chain

Special

! "

# $ % &

' %(

) # $ % &

' %(

* +# + , ! " -" -.

/ 0 #

-

! " -" -.

12 3 4 2 15 3 531

)51 6 31

Six grain conditioning tips

A

common misperception is that grain can be held above 15%

moisture without risking quality or loss of net income.

To safely store maize postharvest through the following

spring, moisture content generally should not exceed 15%. To safely

store through the winter, it should be no higher than 14% and to store

grain for one year or longer, it should be no more than 13% moisture.

Small grains do not drop as much, but they should be targeted at

least a point below 13% to hold more than a year.

Check with local grain conditioning experts, too, because specific

recommendations vary from location to location.

Here are some helpful tips:

As grain enters the bin, run aeration fans to equalise kernel grain

moisture, which typically takes five to ten days. This puts the

grain in the best shape to store safely.

Fines can’t be thrown as far as kernels. Repetitive coring that

forms an inverted ten foot cone for every ten feet of depth as

the bin is filled, is a tremendous tool in minimising fines in the

centre.

Soon after harvest, pull the bins with peaked grain down so the

centre is just below the maize at the wall. The grain will look

somewhat like an ”M“ from the side, promoting air movement in

the centre. Levelling at this point is also a good practice.

Watch the ambient temperature, and use aeration fans to get

the grain temperature below 10°C as soon as possible. Nearly all

insect and mould activity ceases below this temperature.

Don’t completely empty one bin at a time when time comes to

sell the grain. Instead, take partial amounts from multiple bins to

form the ”M“ shape and move the remaining grain around. That

not only promotes air movement, but also reduces the risk of

grain plugging the discharge.

Check the grain weekly. Climb to the top of the bin, without

entering and observe whether there is a crust or any noticeable

smell. An increase in surface moisture usually is the first sign of

problems.

GARY WOODRUFF,

grain handling applications manager: GSI

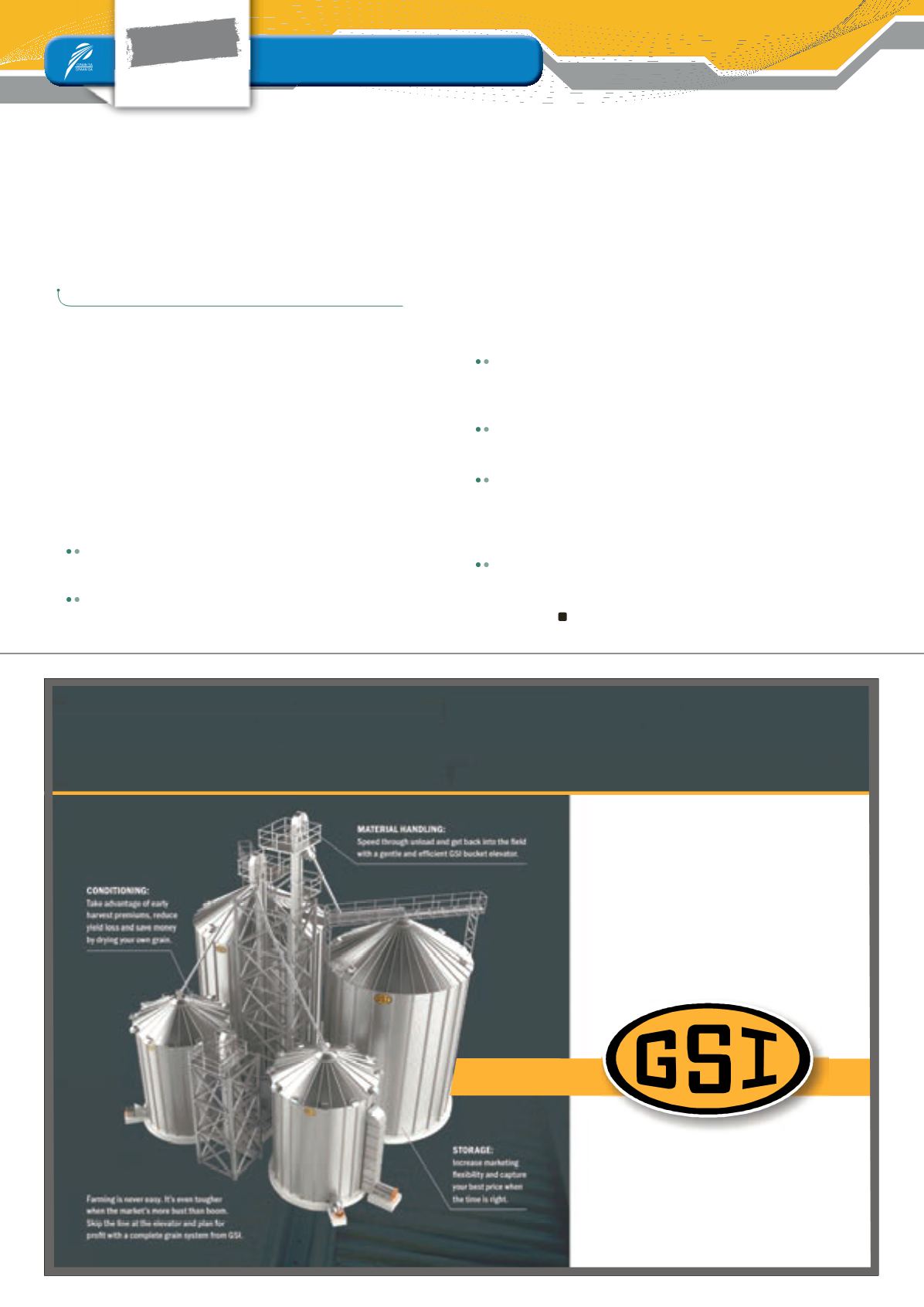

Product information