Augustus 2018

56

Establishing the vegetation

of cover crops on big farms

A

s a result of requirements from the European Union, there

are now increased demands for more frequent usage of

cover crops in a crop rotation system. This requirement

is very problematic, especially for producers who have a

larger acreage and are fighting against time.

One of the options on how to establish a vegetation of cover

crops on big farms is using a combination of a Ferti-Box and a wide

disc cultivator, the SwifterDisc XE 10 000.

Establishment of cover crops

Mr Brueder, who farms in France on an area of approximately

1 000 ha, is a pioneer in the establishment of cover crops with

Ferti-Box. Brueder establishes a mustard crop directly into a

stubble. Mustard seeds are pneumatically transported to the

distribution head, which is placed on the SwifterDisc XE 10 000

disc cultivator.

The distribution head divides the mustard seeds, which pass

through hoses to applicators positioned in front of the rear packer

of the cultivator. This solution offers other possible uses for the

Ferti-Box hopper on farms.

Trash Cutter

The Trash Cutter is a novelty in the accessories for the

SwifterDisc XO_F disc cultivators and the Striegel-Pro straw har

row. The roller consists of sharp edges mounted in a screw. Its small

diameter of 310 mm provides a large circumferential speed at

work and as aresult, good-quality cutting of long crop residue, such

as rape-seed, sunflower or frozen intercrop. The application of

the cutter provides a better quality of crop residue processing in

the following operation.

SwifterDisc XO_F

SwifterDisc XO_F disc cultivators have gone through some

significant changes. The innovated frame structure allows equip-

ping the cultivator with the reinforced front, hydraulically adjustable

levelling bar – the Crushbar for seedbed preparation, or with the

Trash Cutter for cutting crop residue.

The new arrangement of the rear rollers on a parallelogram and

the new technical solution of the spacing washers on the hydraulic

cylinders makes setting the working depth of the discs easier. An-

other innovation is the protection of the screw joints between discs,

bearing boxes and tines. The joints are protected against undesir-

able loosening with anti-vibration washers.

Trash-Fan

As an accessory to the Mulcher machine series, the new Trash-

Fan was designed to suit the needs of our customers. High dust

nuisance and work in a dry environment with high temperatures

may bedangerous not only to the machine, but also to the ma-

chine operator.

An efficient fan solves this issue. The Trash-Fan is a device for con-

tinuous machine surface cleaning. The main part of this device is a

fan that creates a stream of air and directs it to the risk points on the

surface of the mulcher, using wind straighteners.

It brings significant savings to the costs incurred due to cleaning

and also increased labour safety. The device for continuous mulcher

surface cleaning is located centrally on the machine and therefore

it is compact, both for work and transport. The fan is driven by a

hydraulic motor controlled by a hydraulic circuit.

Focus

Implements & equipment

Jan BednáR,

business director, Bednar, Czech Republic

^

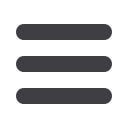

1: The Trash Cutter is

designed for Swifterdisc

disc cultivators and

Striegel-Pro straw harrow.

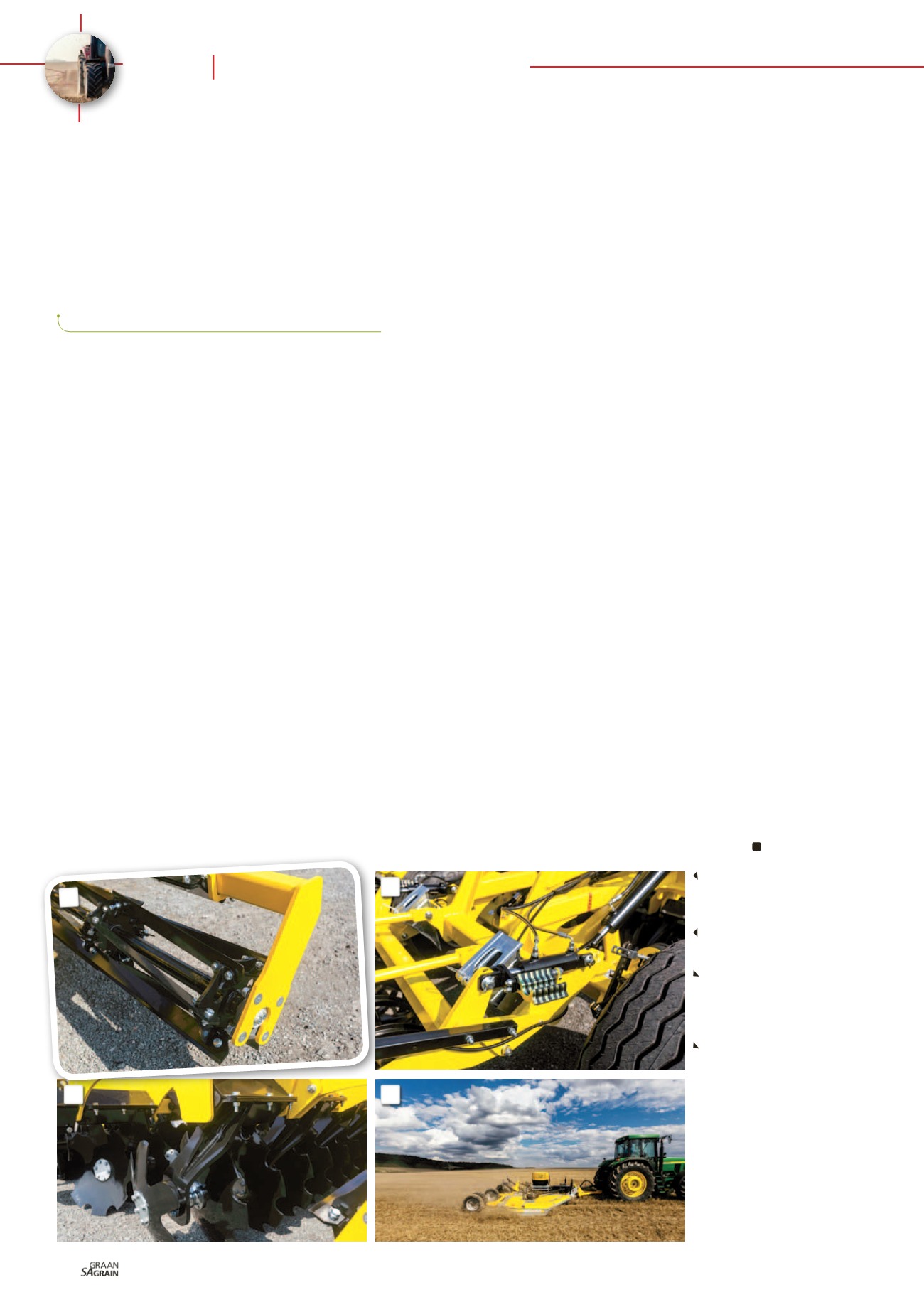

2: A fast setting of working

depth using spacing washers

on hydraulic cylinders.

3: Screw joints between

discs, bearing boxes and

tines are protected against

undesirable loosening with

anti-vibration washers.

4: The Trash-Fan is designed

for crop residue mulcher with

a width of 4,5 m to 7 m.

1

2

3

4

Product information