FoCus

Implements & equipment

VISIT GSIAFRICA.CO.ZA

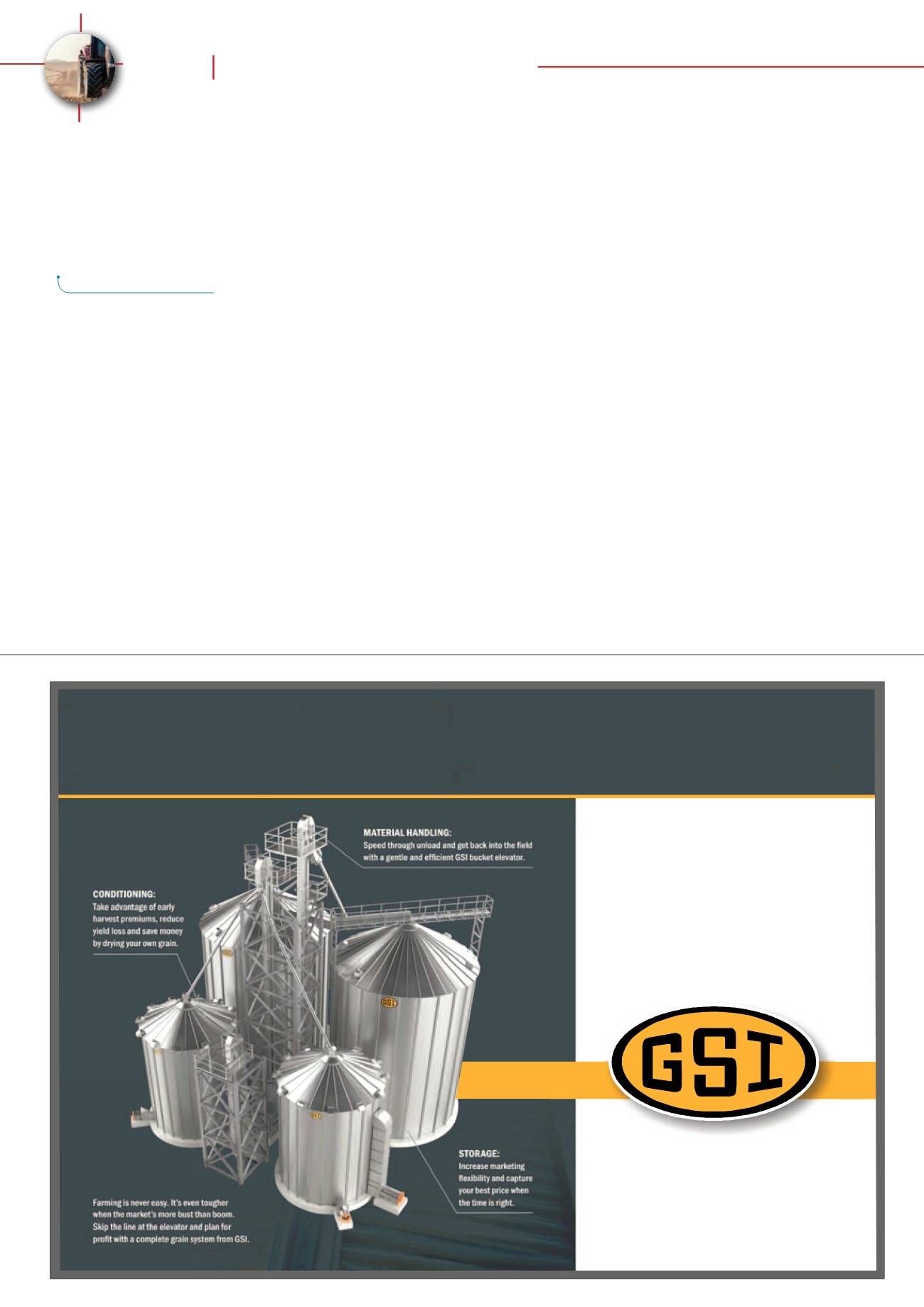

STORAGE

+ CONDITIONING

+ MATERIAL HANDLING

+ STRUCTURES

THE PROFIT CENTER

124 Ridge Road, Laser Park,

Honeydew, Ext 15, Gauteng

P O Box 4012, Honeydew, 2040,

South Africa

Phone: +27 (011) 794 4455

Fax: +27 (011) 794 4515

Email: sales@gsiafrica.co.za

Website: www.gsiafrica.co.za

TURN YOUR OPERATION INTO

PROFIT CENTER

®

Product information

A

grain bin often only has its me-

chanical components run for a

few hours or days each year, and it

has little use for the rest of the

year. The only exception would be grain

aeration equipment.

This can make it more likely that there will

be an issue or failure when these key me-

chanical components are required to per-

form than if they are used regularly, notes

Mr Gary Woodruff, GSI district manager in

Indiana and Kentucky.

’For example, cleaning and maintaining

the electrical equipment, including break-

ers, is often overlooked, but it is an impor-

tant part of a dependable storage season,’

Woodruff says.

Key areas

Woodruff suggests checking the following

key equipment areas before harvest:

Fans and burners

Make sure the fans and burners are clean

and free from obstructions. Some motors

require grease every few years. Follow the

manufacturer’s manual recommendations.

Inspect the blade for damage, and make

sure that the fan turns at full speed with no

vibration.

Some floor supports can move (with vibra-

tion) if grain is not present, so keep this

test to a minimum check. The burners

should have a service inspection at least

every two or three years. All gas lines and

gas components must be kept in an excel-

lent condition.

A test firing of the burner before the season

starts is a good way to prevent problems on

the first day of harvest.

Discharge and power sweep

components

The discharge equipment isn’t usually used

during harvest, unless grain is immediately

transferred – but the only time the discharge

wells, and particularly the inside drive

components of a power sweep, are acces-

sible, is before grain is put in the bin.

Check the motor and service if necessary.

Check the belts for damage and make

sure they are at a proper tension. Replace

if questionable. Lightly lubricate – prefer-

ably with food-grade lubricant – where

grain comes into contact with any area

Safety measures for grain bins

Tom J Bechman,

GSI