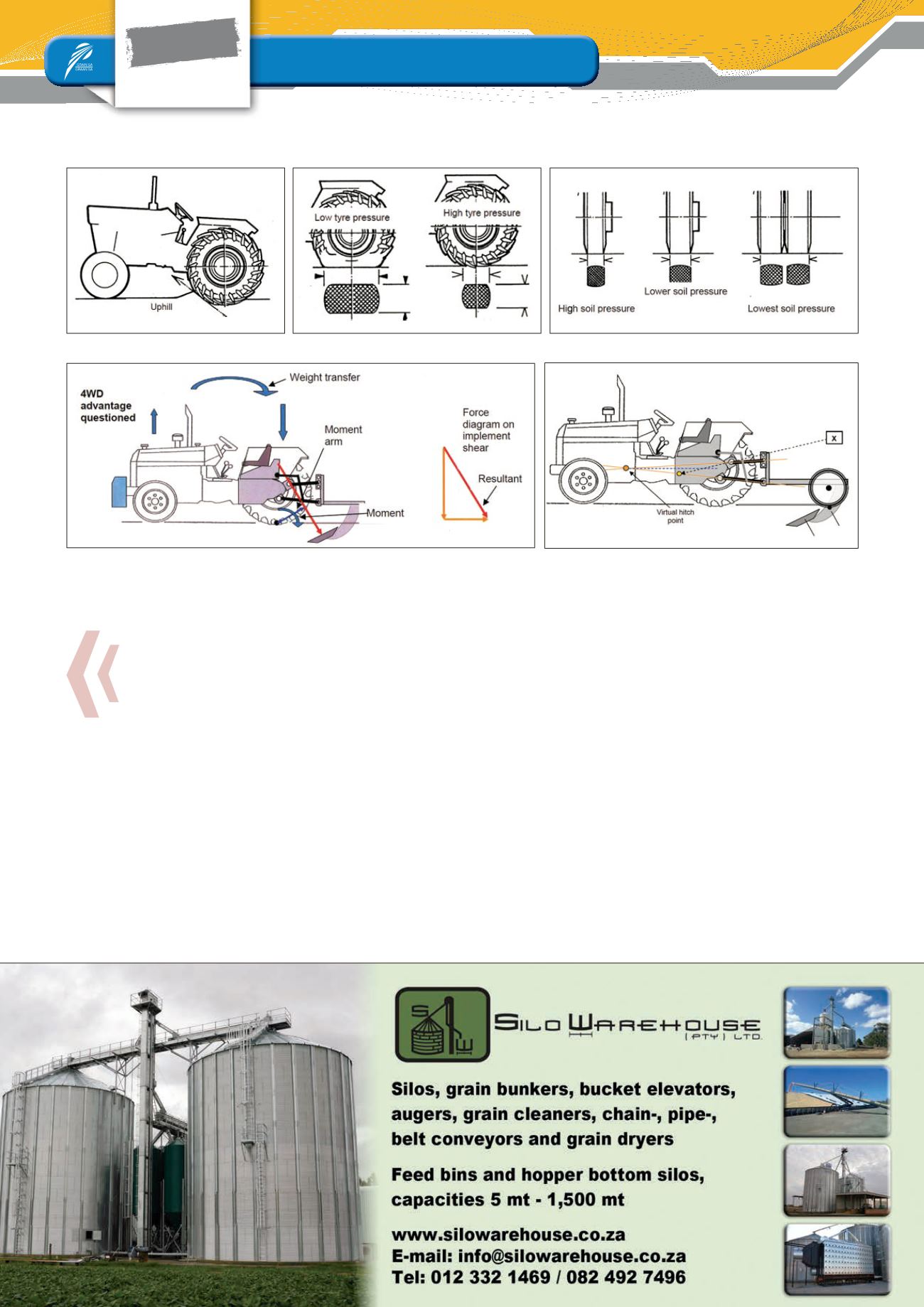

This can be a disadvantage for four-wheel drive tractors, because of

the traction losses at the front wheels of the tractor.

Implement hitching system: Three-point link-

age with depth control wheels

When using a depth control wheel on the implement, the force mo-

ment is between the centre of the ripper shears and the depth con-

trol wheel axle. This causes a downward pressure on both the rear

wheels and front wheels of the tractor. In this way, better traction will

be obtained over the front and rear wheels of the tractor, so a four-

wheel drive tractor will deliver good traction (

Figure 5

).

Different types of rippers

Rippers come in different shapes. The main differences are ripper

teeth shapes, some straight teeth designs and some with an arc

shape. Ripper teeth designs differ from each other because manu-

facturers try to create the best design for their product for best soil

penetration.

Then there are also the different ripper teeth shears that are being

used. The shears of course help to effectively loosen the soil. Manu-

facturers come with different ideas of shear designs to loosen the

soil. In most cases, the ripper shears are mounted at an angle to

achieve better penetration.

The other important component that is sometimes added is depth

control wheels, especially on the larger ripper frames. The function

of the depth control wheels is of course for more effective depth

control, but also to balance the weight and traction between the

tractor's front and rear wheels, which is ideal for four-wheel drive

tractors or tractors with belt tyres.

Ripping efficiency

Rip processing is not a cheap operation, so it's important to do

the operation as effectively as possible. The purpose of a ripping

operation is to loosen the soil or break a plough-pan layer. Effective

ripping can only be done when the maximum volume of soil is re-

leased. The energy input must therefore justify the output.

FOCUS

Implements and equipment

Special

A look at subsoiler or ripper efficiency

Figure 1: Rolling resistance.

Figure 4: Implement hitching.

Figure 5: Implement hitching with depth control wheel.

Figure 2: Tyre pressure.

Figure 3: Tyre width.