December 2024

| PIETMAN BOTHA, INDEPENDENT AGRI- CULTURAL CONSULTANT |

|

THE INVESTMENT IN TRACTORS AND IMPLEMENTS IS VERY HIGH FOR ANY GRAIN FARMER. A NEW 70 KW TRACTOR CAN EASILY COST R1 million AND THEN ALL THE IMPLEMENTS MUST STILL BE BOUGHT. IT IS IMPORTANT TO MAKE SURE THAT THE TRACTOR YOU BUY CAN PERFORM THE NECESSARY TASKS OVER THE YEARS.

If the tractor is too big or too small for the farm’s work needs, it is going to cost you dearly. To find and buy the right tractor(s) for your farm is a difficult task, but it can be done. Since the introduction of tractors to the agricultural sector, the following question is asked: How many and what tractors should you buy? It makes sense to use a demo tractor to test it on your farm.

FIELD CAPACITY

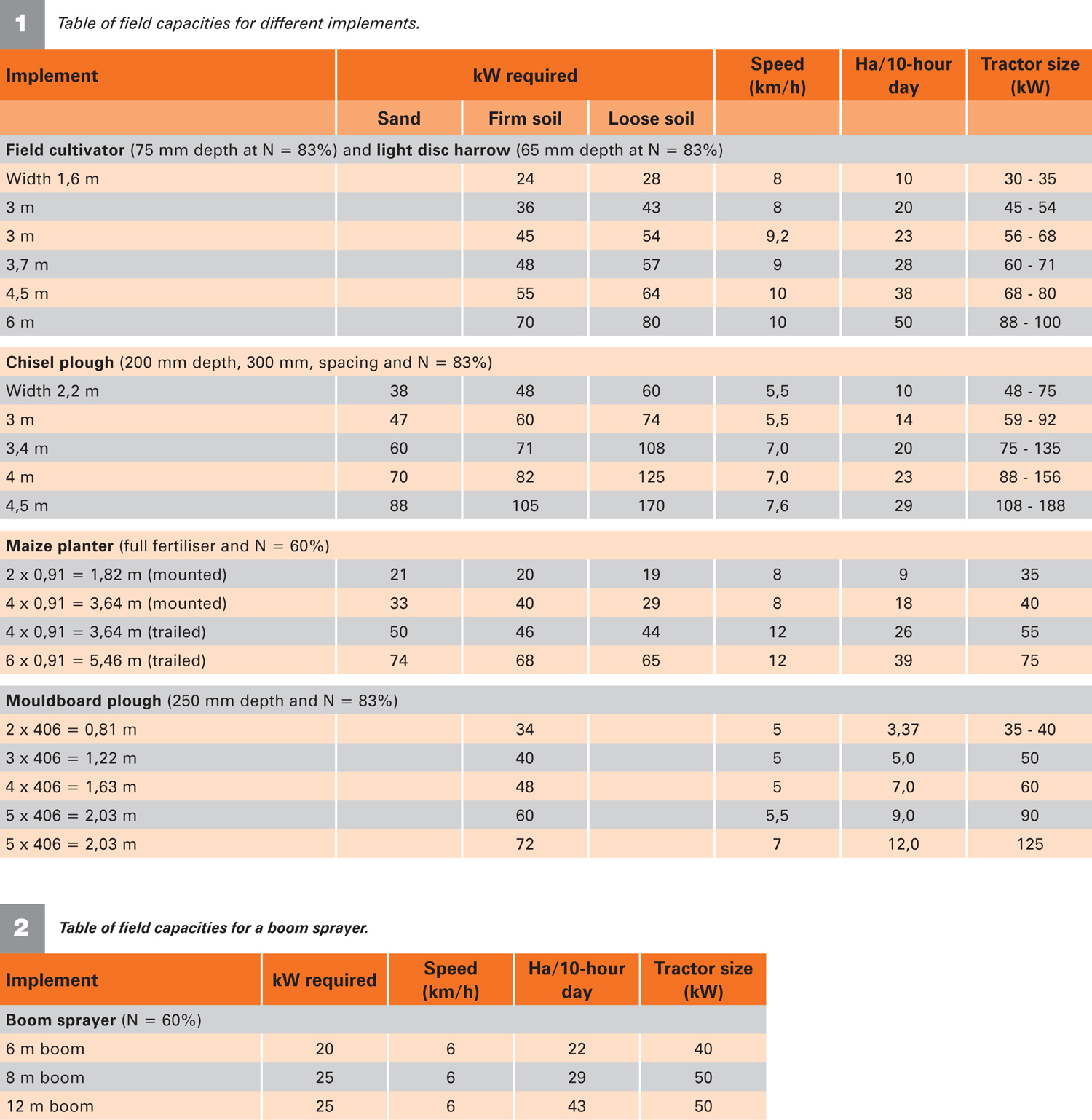

For every cultivation activity and every tractor size, there is a field capacity listed. The field capacity is how many hectares a tractor can work during a 10-hour day.

With just a few calculations, you can determine a tractor’s field capacity. The field capacity is ha/10-hour day = speed in km/h x working width in metres x field efficiency. The field efficiency factor allows for time spent on turning on the headlands, refuelling the tractor, filling seed and fertiliser bins on a planter etc., and therefore it is measured as a decimal. In practice, if the field efficiency is one it would mean the tractor would work the whole 10-hour day without stopping or turning.

Farmers know that this is seldomly possible. It was determined in several field studies that with a tractor only pulling implements, where there is no need to upload or offload fertiliser or seed, the turning at the headlands and refuelling the tractor will take up 17% of the working time. This means that only 83% of the possible work can be done.

With planting, the uploading of the seed and fertiliser can take up to 40% of the time. With the spraying of the crop, only 60% of the time available can be used to spray and the rest of the time is for filling the sprayer. From these efficiency figures it is clear that farmers must make sure everything possible is done to increase the efficiencies of the actions.

With this knowledge, the question of which combination of tractors to buy can be answered. In Table 1 and Table 2 the average field efficiencies for the different operations are given. In practice, these figures may differ from the actual values, depending on how efficiently the operations are conducted, but it is a very good norm. Provision has also been made in the tables for different soils.

In the table of field capacities, the column ‘kW required’ gives an indication of the actual power required to conduct the operation at a specified field capacity. It should be kept in mind that a naturally aspirated engine working under Highveld conditions can only deliver approximately 80% of its rated power as measured at sea level. A turbo-charged engine is assumed not to lose any power with an increase in altitude.

Therefore, if the table indicates that 40 kW is required, a tractor with an advertised rated power of 40/0,8 = 50 kW has to be used. If the tractor is fitted with a turbocharger, a 40 kW turbo-charged tractor would suffice.

A recommended tractor size is specified at some places in the table of field capacities. This is for certain operations where the physical size of the tractor (and not the power of the tractor) determines the field capacity for the operation.

Example

Farmers can make use of contractors to do some of the work, but it makes sense for every farmer to do his own planting and spraying within the planting window of the crops, which is normally 20 working days.

If a farmer is planting 100 ha and the planting must be done in 20 working days, this would mean that at least 5 ha per day must be planted. To plant 5 ha per day, a 5 ha seedbed must be prepared, 5 ha must be planted and 5 ha must be sprayed.

Two 50 kW tractors, such as a Ford 6600 or Massey Ferguson 188, should be enough to do all the work in time. One tractor can prepare the seedbed, while the other one can plant and do the spraying. It is calculated that a 50 kW tractor can prepare a 20 ha seedbed, plant between 18 ha and 26 ha and can spray at least 26 ha per 10-hour day.

So it can work perfectly if one tractor starts with seedbed preparations and the other one starts to plant. The tractor used for planting can then be used to do the spraying of the planted crops later in the day. The next day, the tractor that was used for the seedbed can do the spraying while the planting continues.

If both tractors can do the ploughing of the fields and one tractor can do between 5 ha per day and 7 ha per day, it would mean that the field will be ploughed within 20 days.

By making use of the field capacity figures in the tables, farmers can calculate which combination of tractors to buy. These figures can also be used to check whether the farmworkers are doing their job.

Publication: December 2024

Section: Pula/Imvula