B

KT, one of the world’s top off-highway tyre solution

providers, inaugurated their new Bhuj plant at the beginning

of December 2015.

huj is BKT’s most recent and largest production site. There are

production lines for all market segments such as agriculture,

construction and industrial vehicles as well as earthmoving, port and

mining applications.

More about the plant

The BKT plant of Bhuj (near the Port of Mundra, in the State of

Gujarat) was built in an inaccessible area in a desert. After the start

of construction works in January 2011, an 8 km long pipeline for

drinking water as well as 13 km of electricity lines were laid.

According to Mr Rajiv Poddar (joint managing director: BKT) the new

BKT site covers a total surface area of 126 hectares. An area of almost

10 hectares is dedicated to a modern outdoor track. Tractors and

industrial vehicles equipped with BKT tyres are tested there. Their

state-of-the-art R&D Centre, which will be completed by early 2016,

contains an innovative structure, where research on new polymers

is done and new tread compounds are developed.

’Our researchers, engineers and technicians can boast of having the

most advanced equipment for chemical, physical and mechanical

testing,’ Poddar said.

The central area in the plant hosts the production house that

streches over 29 hectares. Looking at figures and dimensions, Bhuj

is a very impressive industrial complex. Yet, it is more than just a

prestigious entity for production, research and testing.

On over 6 hectares of the Bhuj site a small town for the employees

was built including modern flats for 406 families, a mall, a green area,

a recreation centre, a medical centre and a fire station. In addition

there are 90 rooms for university students who take part in an

industry-university co-operation project.

Even though the entire project will only be completed by the end of

2016, the first tyre rolled off the production lines in March 2012.

Currently BKT has a production capability for the sizes ranging from

17,5” to 49” and in 2016 it will go up to 51”. They are proud of having

a very extensive range of radial agricultural tyres consisting of over

230 sizes, and also being the leading manufacturer of agri radial

tyres across the globe.

Visit your local Tubestone dealer for more information on BKT

tyres.

(More information about the tyres currently produced in Bhuj was

published in the February 2016 issue of

SA Graan/Grain

. – Ed.)

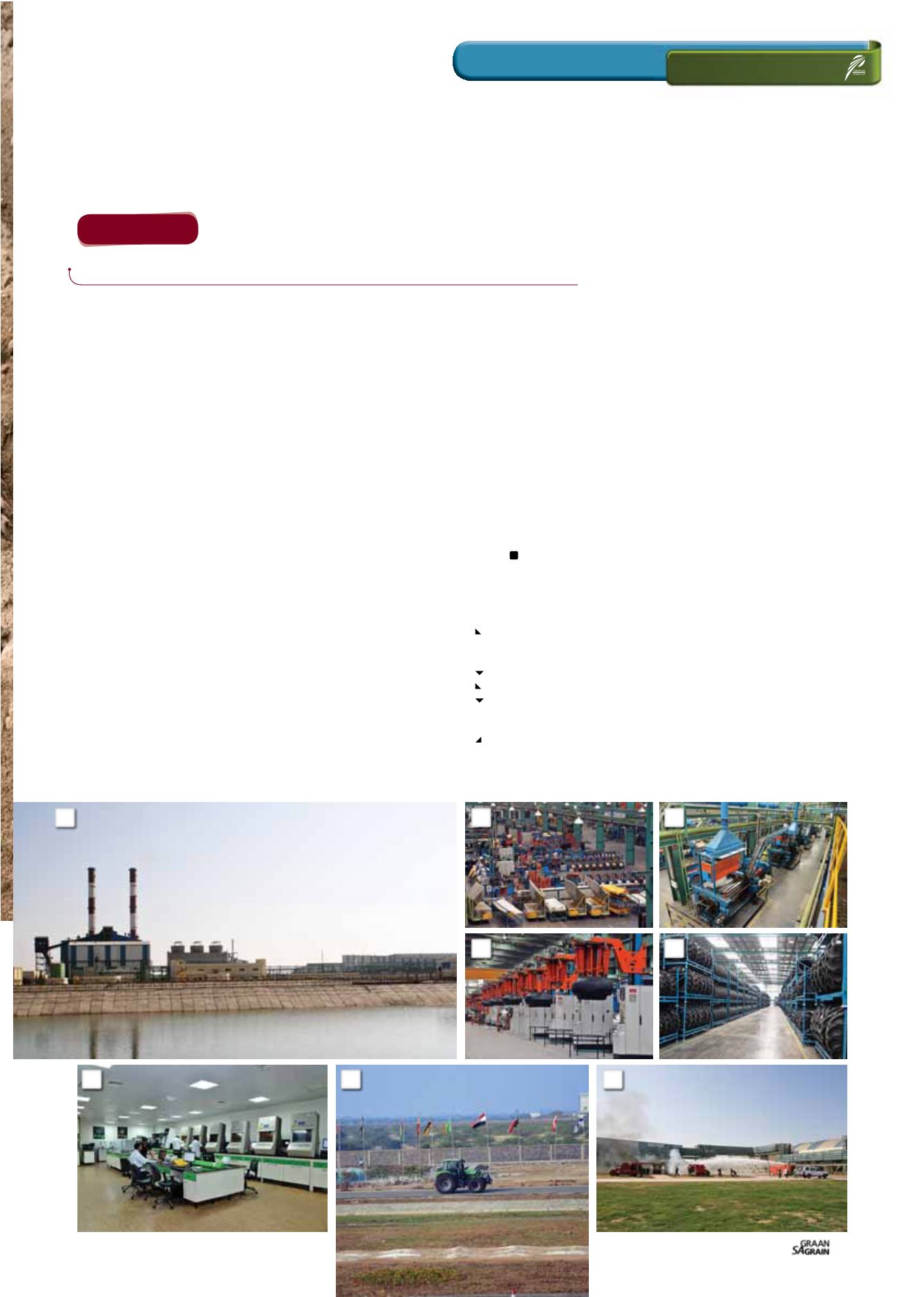

1: A thermoelectric power plant meets the requirements for water

vapour and electricity throughout the entire site. Enormous water

collection tanks provide water reserves even in droughts.

2a - 2d: Inside the plant – which is now ready to serve demand.

3: The Bhuj Lab.

4: The testing track, the one and only in India, has been set up to

test tyre performance and driving comfort on different surfaces from

uniform road conditions to rough terrain.

5: The Bhuj plant also has its own fire station with seven firefighting

trucks, two ambulances and a smooth firefighting system covering

the entire complex. The fire brigade also takes action even in case of

emergencies outside the Bhuj plant.

107

March 2016

RELEVANT

Company ready to change the game

with new production plant

ESTIE DE VILLIERS,

editor:

SA Graan/Grain

and

LAURA PEDRALI,

European press office: BKT

– PART 2

1

3

4

5

2a

2c

2b

2d