FOCUS

Groundnuts

Special

The importance of a good

groundnut harvesting process

T

he harvesting of groundnuts can be done by hand, but it

requires a lot of man-hours. Rovic Leers is supporting the

producer through mechanising the harvesting process of

groundnuts with the use of a digger shaker inverter and a

harvester. Both machines are manufactured by the Kelly Manu-

facturing Company (KMC) in Georgia, USA.

The digger shaker windrower is used to lift groundnuts and de-

tach them from the soil and to dig deep enough to prevent cutting

pegs. Vines are undercut and lifted gently for transfer to the invert-

ing drums.

Broad rattler bars and wide inverting drums allow for acceptable in-

verting in the largest of vine conditions, even if the operator gets

off the row. Windrow-inverting attachments orient plants as they

leave the nuts primarily on top of windrows to permit greater air cir-

culation and exposure to sunlight for a shorter drying time.

Efficient dirt knocker wheels are adjustable for removing soil, rocks

and foreign material from vines. Rovic Leers supplies a two-, four-

and six-row machine, with the standard row width of 0,91 m row

spacing (0,76 m row spacing on request).

Taller height of the windrow keeps groundnuts off the ground

during rainy weather to preserve quality with minimum loss. Nar-

row widths of windrow ensure tractor tyre space and prevent knock-

ing off the groundnuts. The KMC digger shaker inverter can work

at speeds up to 7 km/h and delivers a clean windrow. No extensive

time-consuming daily maintenance and easy access to all working

components offer a low repair expense and minimum down time.

Windrowed groundnuts could be combine-harvested wet (35% to

50% moisture), semi-dry (18% to 25%), or dry (8% to 10%). These

pods could reach a semi-dry condition (seeds rattle in pods) one to

three days after digging.

So it is of great importance to have the right equipment to harvest

all the groundnuts at the right time. Rovic Leers supply a six-row

tractor-drawn combine that can work at speeds of up to 6 km/h.

The KMC combine harvester comes with a camless pick-up for a

smooth consistent vine flow and can handle six rows of 0,91 m spac-

ing with ease.

Equipped with a double swivel gear hitch, it offers a smoother

and sharper turn. A large basket of 11,5 m³ with a high pivot point

allows for better emptying into a dumpcart which leads to fewer

stops for unloading. Also available is the unload on-the-go model

that is equipped with a conveyor that allows offloading into a dump-

cart while driving. This helps to harvest more hectares per day and

thereby increases productivity.

In wet conditions a KMC groundnut vine conditioner can be

considered before harvesting. This allows groundnuts to dry fast-

er, permitting combining earlier in the morning or earlier in the

season. It removes dirt and foreign material for improved grades,

as well as fluffing and lifting vines while returning windrow to pre-

vious inverted position. Rovic Leers offer the vine conditioner in a

six-row 0,76 m rigid or 0,91 m folding model.

Rovic Leers and KMC groundnut machines provide faster, more

productive groundnut harvest and offer a comprehensive after-

sales service support with a dealer network of over 100 branches

nationwide.

31

February 2016

Product information

WILLIE HUMAN,

sales manager: Johannesburg, Rovic Leers

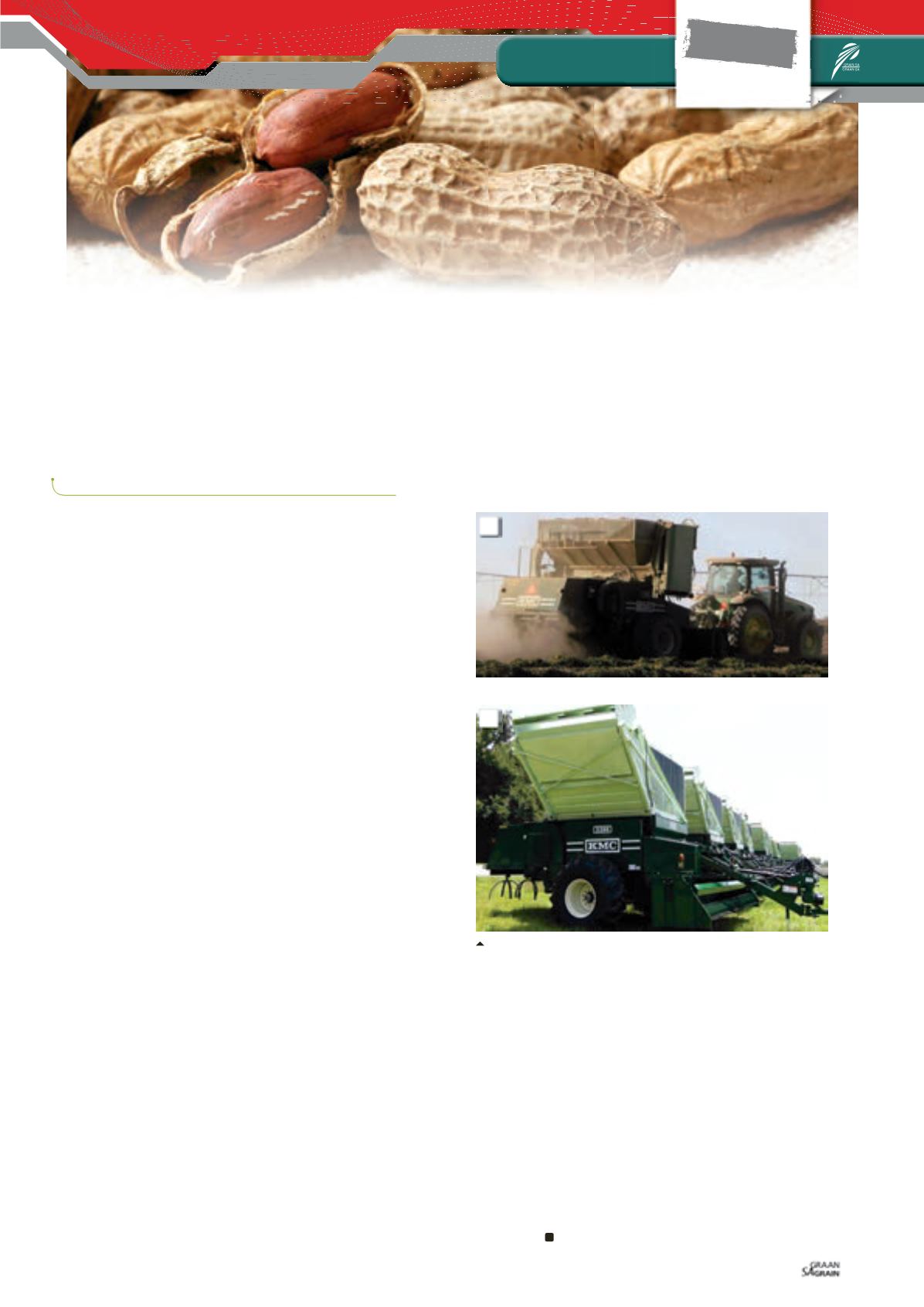

1a and 1b: KMC groundnut combine harvesters.

1a

1b