Februarie 2019

18

F

luctuating crop prices, droughts and

then rain in the harvest period; these

are only some of the woes to be

dealt with by South African ground-

nut producers. The recent history has been

a challenging one, and groundnut produc-

tion remains largely dependent on favour-

able climatic conditions – especially during

harvest.

The KMC range of groundnut harvesting

equipment from Rovic Leers is a well-known

and respected brand, comprising of the

following product categories:

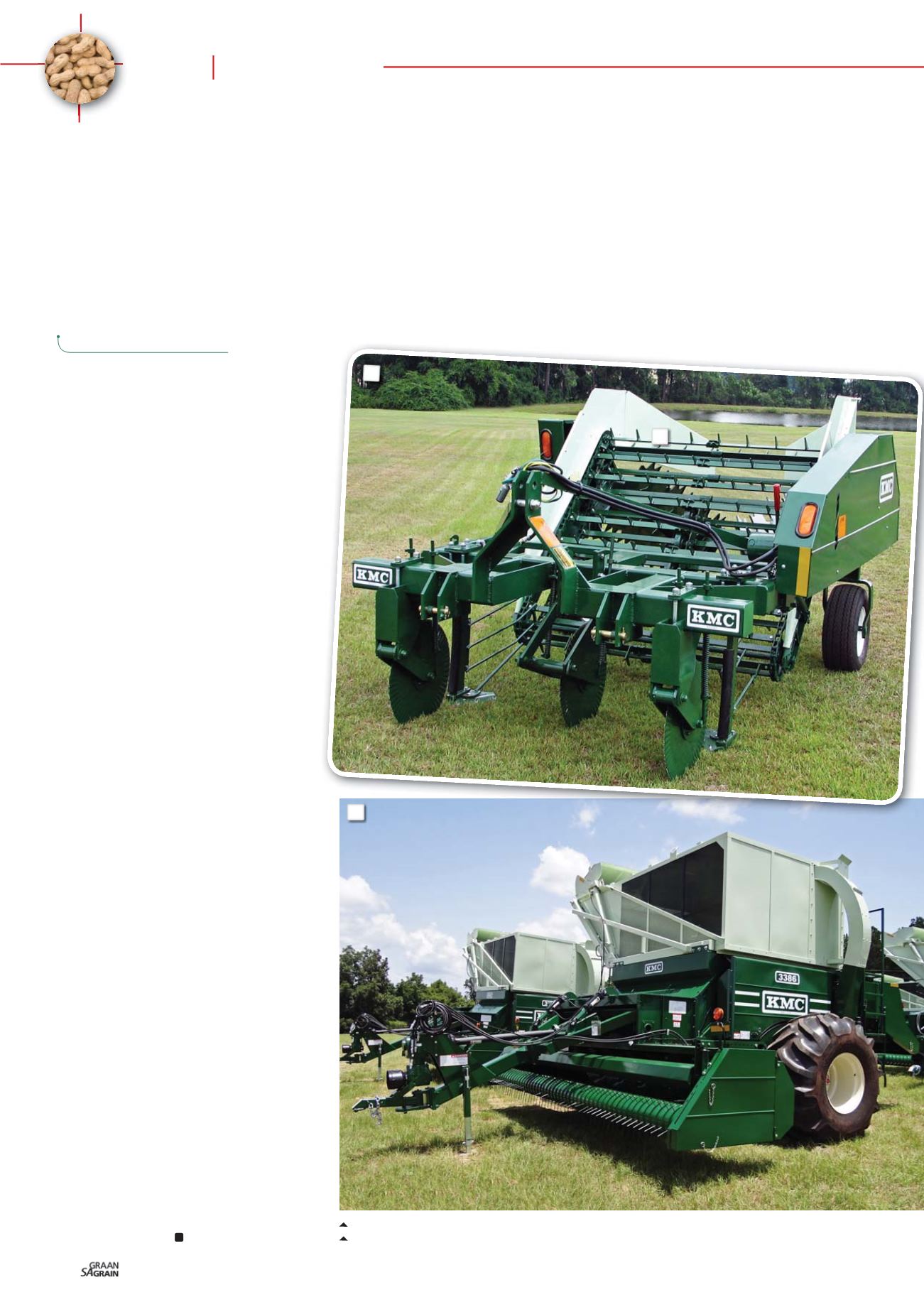

Digger, shaker inverters

These are available in two and four row

units, handling 34” - 40” rows (two row)

and 30” - 32” or 36” - 38” (four row) planting

widths. They are equipped with patented

and adjustable dirt knockers, and easy set

up adjustment for heavy vine conditions,

hydraulic drive and a chain conveyor for ef-

fective crop lifting and inverting.

Vine conditioners

Available in six row units for row widths of

34” - 38”, they are designed to use after lift-

ing the crop to remove excessive soil and

foreign material, to ready the crop for effec-

tive harvesting.

Combine harvesters

Hopper capacities of 3 400 kg, a small di-

ameter pick-up reel, a large diameter auger,

and handling six rows (36”) make for a high-

ly efficient harvesting solution.

Available with an optional ‘On The Go’ un-

load system to improve harvest capacity

even further.

The best news: Rovic Leers has made a

management decision to make this 2019

harvesting season easier for our producers.

This means a dramatic price reduction and

very special pricing on our available KMC

stock – mostly because we invested in stock

at good exchange rates, and are passing it

on to the end user.

Serious about

helping

our producers

FOCUS

Groundnuts

Mini-

Product information

MARIUS RAS,

Rovic Leers

1

1

2

1: KMC groundnut digger, shaker inverter.

2: KMC groundnut harvester.