113

September 2018

relevant

Maize quality 2016/2017

The 100 kernel mass (‘as is’ basis) of white

maize (35 g) averaged higher than yellow

maize (33,5 g). This trend was also obser

ved in previous seasons. The percentage

yellow maize kernels above the 10 mm

sieve were on average 10,7% lower than

white kernels and the percentage yellow

kernels below the 8 mm sieve 9,3% higher

than that of white maize. White maize ker-

nels were larger than in the previous two

seasons, while the yellow maize kernels

were still some of the smallest over the past

ten seasons.

Both white and yellow maize were slightly

more susceptible to breakage than during

the previous season. The percentage stress

cracks observed varied overall from 0%

to 50%, and averaged 8% for both white

and yellow maize – 3% higher than in the

previous season.

Milling Index

Milling Index is an indication of the milling

abilities and milling quality of maize kernels,

where a higher Milling Index means a high-

er extraction of the high-grade and most

profitable products like samp, maize rice

and maize grits (degermed products) that

are manufactured from the corneous part

of the endosperm.

The Milling Index is a model developed

on the Foss NIT Infratec 1241- Generation

3 Standard Version Grain Analyser where

the NIT spectra were modelled against the

Roff milling fractions. In the previous sea-

sons (until 2015/2016) the Milling Index of

the samples were determined with the cali-

bration model developed by the ARC-Grain

Crops. With this model, the average Milling

Index of a sample with good milling charac-

teristics is about 95 with a variation of about

55 (low milling quality) to about 115 (very

good milling quality).

The SAGL was tasked by the Maize Trust

to develop a new model for Milling Index

using samples from maize cultivar trials

supplied by the ARC-Grain Crops and by

commercial seed breeders over four sea-

sons (from 2012/2013 onward). The trials

included a range of hardness levels. The

New Milling Index (NMI) that was devel-

oped is similar to the original ARC formula

but on a 14% moisture basis, and with the

constants removed. The NMI model has

improved precision compared to the older

version, due to the almost tenfold increase

in the number of samples used to build

the calibration model.

During the fifth year, samples of commer-

cial hybrids, selected imported maize sam-

ples and outlier samples from the 2014/2015

and 2015/2016 seasons were included to

develop a robust model with the assistance

of FOSS to produce accurate results. The

improved new model, SAGL Milling Index

2017, now includes two parameters, SAGL

Milling Index (SAGL MI) as well as a new

parameter namely Grit Yield All (GYA).

SAGL Milling Index indicates the relative

ratio of total hard endosperm products

(B2 grits, B3 fine grits and B3 coarse grits)

to offal products (B1 fine flour and total

chop/bran) as determined on a Roff mill

and used for calibration of the NIT. It is ex-

pressed as a dimensionless index value

according to the scale in

Table 1

.

Grit Yield All is defined as the sum of the

mass fractions of the Roff B2 grits, B3

fine grits and B3 coarse grits fractions ex-

pressed as a mass percentage of the total

mass of the whole maize before milling.

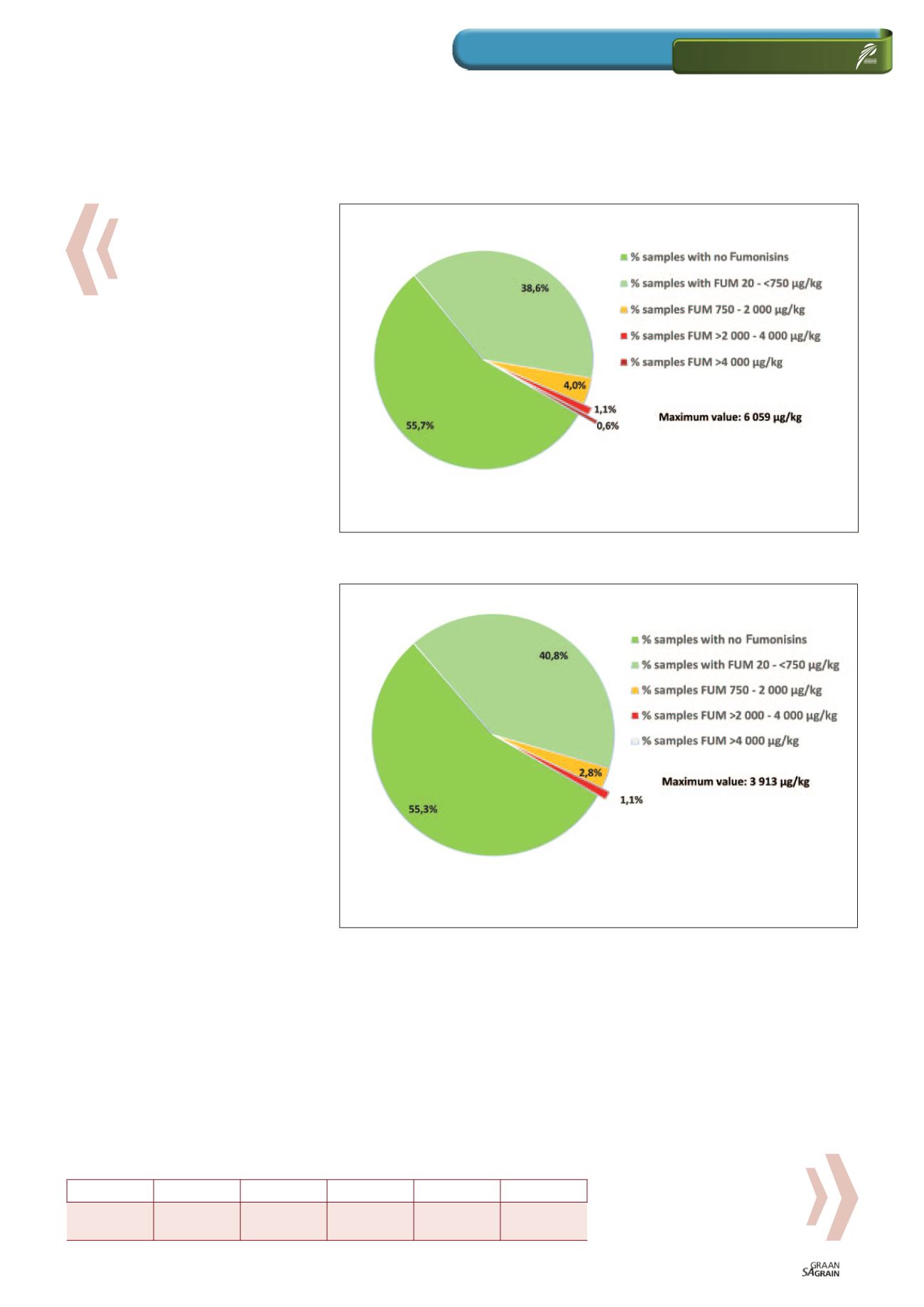

Graph 4: Fumonisin occurrence in the 2016/2017 maize crop.

Graph 5: Fumonisin occurrence in the 2016/2017 white maize crop.

SAGL MI

<40

40 - 60

60 - 80

80 - 100

>100

Description

Soft

Medium Moderately

hard

Hard

Very hard

Table 1: The dimensionless index value.