agrochemicals, soil can recuperate with

microorganisms breaking down unwanted

chemical substances.

The practice

At Humanskraal a field trial of 53 ha of a

diverse summer cover crop mixture was

planted, which included grasses, legumes,

cash crops and radish. Two planters were

used to plant the big and fine seed sepa-

rately on the same field. The planting den-

sities for both big and fine seeds were

110 000 seeds/ha. The aim was a total of

220 000 plants/ha.

The fine seeds were planted at a 30˚ an-

gle on top of the big seed rows. The direct

drilling of seed in rows brought a saving on

seed cost of 50%, compared to broadcast-

ing.

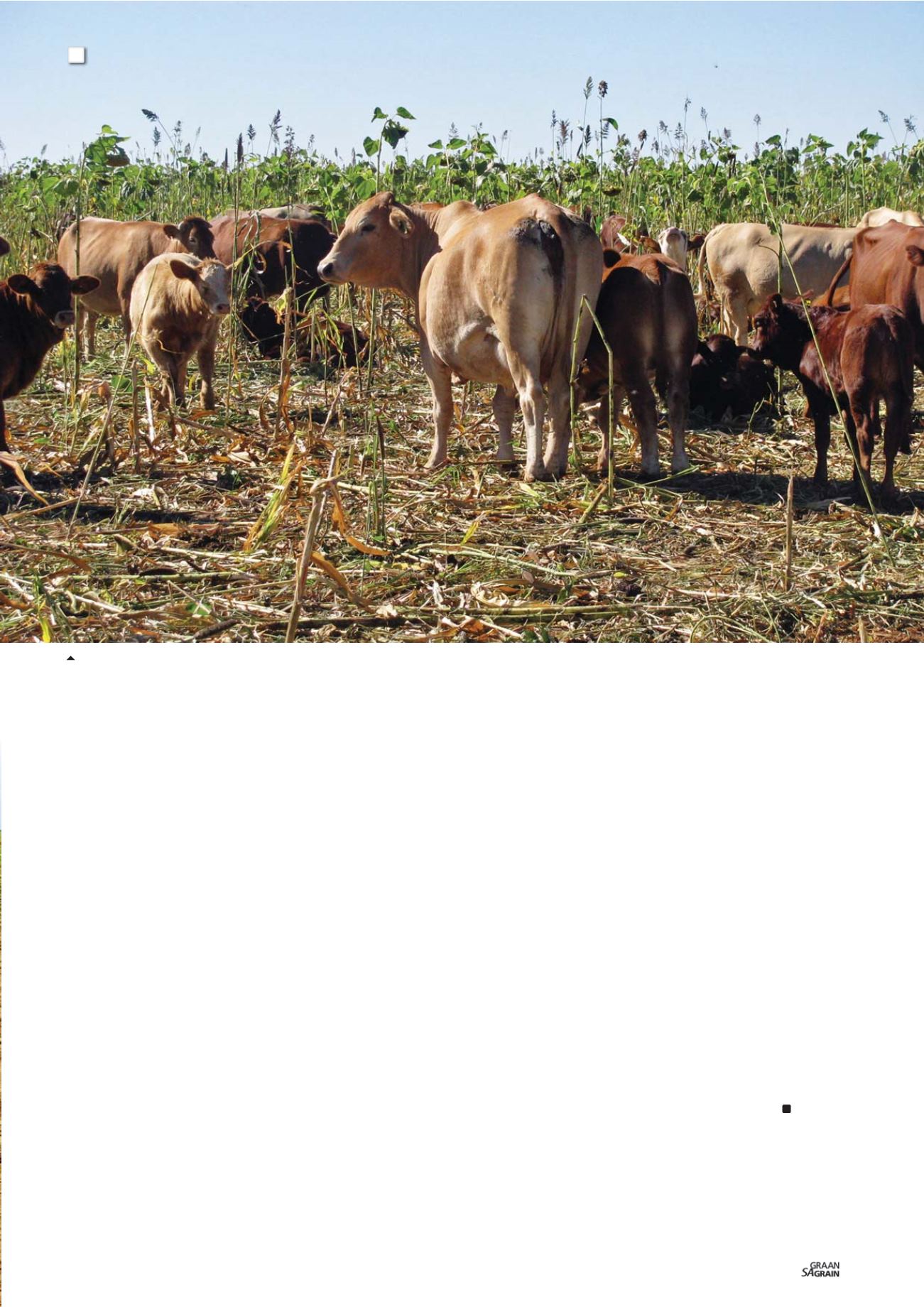

Photo 2

is testimony of the successful

establishment of the cover crop. Planting

took place on 16 January this year, whereas

the photo was taken on 1 February.

Grazing

Livestock was bought at an auction at

Vryburg and transported by truck to the

farm Humanskraal of Mr George Steyn

(

Photo 3

). Due to the high prices of weaners

at the time, cow/calf pairs were bought, 200

in total, which equates to 150 livestock units

(LSU), with an estimated dry matter need of

2 034 kg/day.

Electric fencing equipment was used to

divide the field in grazing camps of 3 ha

each. These camps were used for a period

of three days before moving livestock to a

new camp. An inclusion area was also iden-

tified where animals could be put in case of

extended rainy events. A perennial warm

season grass pasture of Smuts finger close

to the cover crop was identified as suitable

for this purpose. Water was supplied at a

central point with a corridor on the side of

the field trial giving livestock access to the

water.

Discussion

The most nutritional leaves and seed

heads were consumed by animals. Most

of the more fibrous stems were trampled.

This created a mulching effect that cover

the soil surface completely as shown in

Photo 3. Meat production was in the order

of 215 kg/ha with a feed conversion ratio

of 10.7:1. A total of 11,4 tons of meat was

produced on 53 ha in 60 days.

Graph 3

on

page 41 gives us a breakdown of the bio-

mass that was produced by the cover crop.

Selling at an auction meant that a 7% com-

mission fee had to be paid to the auctioneer

at the cost of R120 000. Transporting the

livestock also had high cost implications.

According to Steyn, buying livestock at

an auction is risky and you might just

end up buying another producer’s pro-

blem animals.

Using your own animals will be less risky

and will add value to your own livestock,

which made more sense to him. The field

trial will become a monitoring site for future

reference.

Conclusion

Restoring soil organic matter back to natu-

ral levels before tillage started, will not be

easy. However, diversifying crops and live-

stock has certainly shown to speed-up the

biological and recovery process.

Producers are urged to start their own strip

trials, comparing and repeating CA practic-

es discussed in this article over a number

of years. Producers should be innovative,

not relying on recipes, adapting each farm

within its own realities. There is no ‘one size

fits all’.

All CA principles should be implemented

with good quality (minimal soil disturbance,

diversity, mulch, livestock integration, liv-

ing roots), which will help to revive soil life

and to feed and protect them.

References

Lal, R. 2016.

Soil health and carbon management

.

Food and Energy Security 5, 212 - 222.

Montgomery, DR. 2017.

Growing a revolution: Bring-

ing our soil back to life

. Norton and Company: New

York, USA.

Moore-Kucera, J. 2016.

Soil organisms

. Soil Health

Division: NRCS USDA.

43

November 2018

3: Livestock grazing cover crops.

3