Oktober 2017

38

Variable rate irrigation technology

– determine the economic benefit

E

ver increasing production costs are a serious threat to the

sustainability of irrigation producers. Over the past 15 years,

production costs of wheat and maize under irrigation in-

creased significantly. The major contributors towards the

increase in production costs are fertiliser, seed and irrigation costs.

Increases in irrigation costs are due to ever increasing electricity

costs. The recent increases in electricity tariffs have created seri-

ous problems for irrigation producers. Thus, irrigation producers will

need to evaluate different options to manage electricity and water

costs in the future.

Significant opportunities exist for irrigation producers to reduce

electricity costs through irrigation system design, renewable ener-

gy resources and operating practices to improve profitability.

Renewable energy resources (wind energy, hydroelectricity and

solar panels) require a large amount of capital and are not always

affordable to irrigation producers with a cash flow constraint. The

design of an irrigation system and the operating practices need to be

evaluated in order to reduce electricity costs.

Potential electricity savings can be achieved by adopting new tech-

nologies such as variable speed drives, high efficiency motors and

variable rate irrigation. Variable rate irrigation allows the irrigator to

apply different volumes of water to each section of the field which

maximise yields and profitability (Lindsay, undated).

Variable rate irrigation has a few potential benefits for the irrigator,

which include the following (Lindsay, undated):

Savings in electricity costs

Easy to use – saves time

Efficient watering

Customised to specific field needs

Different application rates for different soils or crops save

water, energy and fertiliser/chemicals

Reduces overwatering on laterals and part circle pivots

Saves water as individual sprinklers or zones can be turned

off over tracks, drains, creeks and bridges

Decreases and eliminates watering in low or flooded areas

Reduces leaching and runoffs on tighter soil areas

Less track maintenance

However, despite all the potential benefits, it is important to com-

pare the investment costs of variable rate irrigation with the potential

electricity cost savings, thus, taking cognisance of the trade-off be-

tween investment costs and electricity costs.

When variable rate irrigation is applied to an irrigation system the

flow rate and pressure requirement of the system change, since dif-

ferent volumes of water are applied to each section of the field. The

change in flow rate and pressure requirement change the kilowatt

usage and irrigation hours of the system, which change the electric-

ity costs and can lead to electricity cost savings.

FOCUS

Irrigation

Special

MARCILL VENTER,

Department Agricultural Economics, University of the Free State

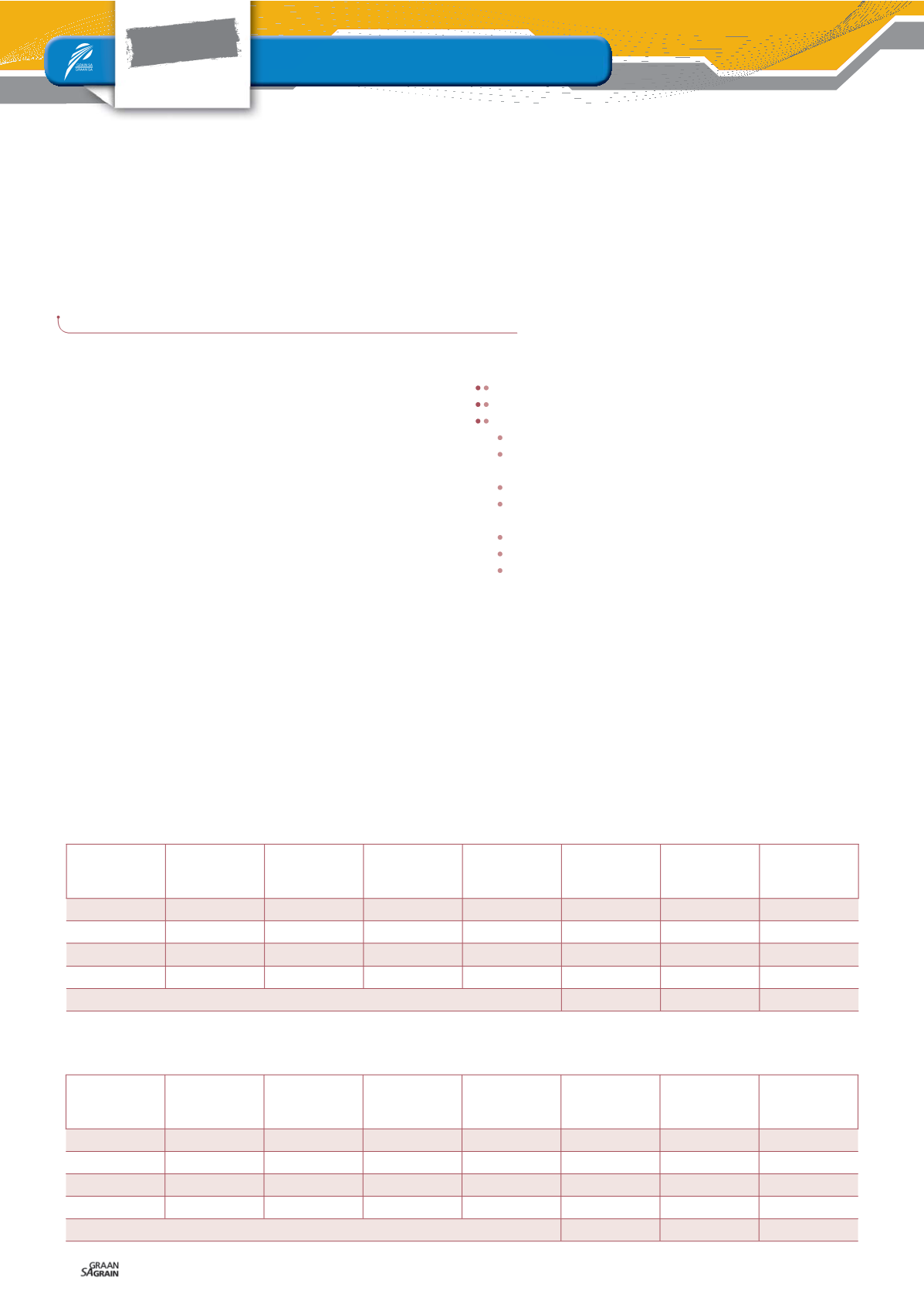

PERCENTAGE

OPERATING

TIME (%)

FLOW RATE

(M

3

/H)

PRESSURE

REQUIRE-

MENT (M)

KILOWATT

(KW)

PUMPING

HOURS

(HOURS)

VARIABLE

ELECTRICITY

COSTS (R)

FIXED

ELECTRICITY

COSTS (R)

TOTAL

ELECTRICITY

COSTS (R)

30%

100,5

21,1

16,2

827

7 827

4 211

12 038

50%

125,5

22,4

21,8

1 118

13 900

7 019

20 919

10%

150,5

24,1

24,9

186

2 639

1 404

4 043

10%

178

22,9

29,6

160

2 688

1 404

4 092

Total

27 054

14 038

41 092

TABLE 1: PARAMETERS AND ELECTRICITY COSTS FOR USING VARIABLE RATE IRRIGATION TECHNOLOGY

FOR HIGHER OPERATING TIMES AT LOWER FLOW RATES USING RURAFLEX.

TABLE 2: PARAMETERS AND ELECTRICITY COSTS FOR USING VARIABLE RATE IRRIGATION TECHNOLOGY

FOR HIGHER OPERATING TIMES AT HIGHER FLOW RATES USING RURAFLEX.

PERCENTAGE

OPERATING

TIME (%)

FLOW RATE

(M

3

/H)

PRESSURE

REQUIRE-

MENT (M)

KILOWATT

(KW)

PUMPING

HOURS

(HOURS)

VARIABLE

ELECTRICITY

COSTS (R)

FIXED

ELECTRICITY

COSTS (R)

TOTAL

ELECTRICITY

COSTS (R)

10%

100,5

21,1

16,2

276

2 609

1 404

4 013

10%

125,5

22,4

21,8

224

2 780

1 404

4 184

50%

150,5

24,1

24,9

932

13 196

7 019

20 215

30%

178

22,9

29,6

479

8 064

4 211

12 275

Total

26 648

14 038

40 686