Common soil preparation mistakes

August 2015

NERISSA HECHTER, marketing manager: Radium Engineering

Since the effect of soil preparation occurs under the soil, it is very difficult to detect faults. Normally a producer will only experience a drop in yield and not necessarily relate it to soil preparation mistakes.

Since the effect of soil preparation occurs under the soil, it is very difficult to detect faults. Normally a producer will only experience a drop in yield and not necessarily relate it to soil preparation mistakes.

The first and biggest mistake producers make, is not making use of a good soil profile pit, in this pit the necessary actions that are needed can be detected. A profile pit that represents the dominant soil types needs to be inspected. This way the best implements to solve the problem and the working depth can be determined.

It is also important that producers need to know what the aim of the soil preparations are. Is it to mix in the lime with the soil, or to break a plough pan? This will also play a part in what action needs to be taken.

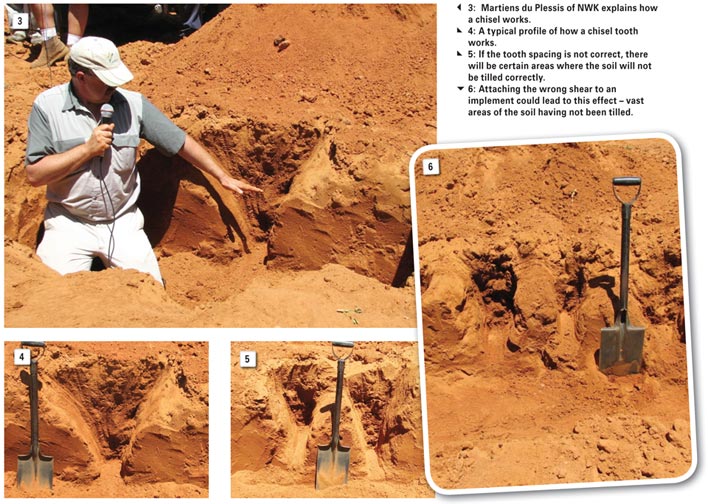

Each implement type creates a unique soil braking profile and every producer should know which machine will work best to solve their specific soil problems. Soil consists of sand, slick and clay; with the different combinations of these components, various actions are needed. This will also help to determine the required working depth.

The placement of a tillage machine and working depth will determine how the soil profile is broken up. Producers are encouraged to understand the working and setting of their machines.

With more than 80 years of agricultural and technical experience between father and son, Mike and Grant Roest from Radium Engineering, provide more insight into the common mistakes producers make with their tillage machines.

- The first and foremost mistake of all is the lack of operator training. Farm workers are the workers that are central to the productivity and success of any farm. By giving the tractor/machine operator proper training, it provides them with the necessary skills and knowledge to carry out their job to the best of their ability, increasing productivity and the quality of work.

- Maintenance is key to ensure that all equipment required for production is operating at 100% efficiency at all times. Through short daily inspections, cleaning, lubricating, and making minor adjustments, minor problems can be detected and corrected before they become major problems.

- Going hand in hand with maintenance is the lack of supervision by the producer or farm manager, by spending 30 minutes a day ensuring that the tractor and implement is set correctly, not only will your maintenance decrease by 75%, but your yield will increase substantially.

- Mike further explains that producers need to educate themselves regarding their machines, thus making sure that they do not over-use the machine by making it work beyond its design.

- The spring release system or stump jump mechanism cannot work forever – the more rocks and obstructions you have in your fields, the quicker this mechanism is going to wear out.

- Your soil conditions are also a very important factor to keep in mind when you start tilling your soil. Soil should be slightly moist, and then it will break and crumble in textbook fashion.

- When buying a tillage machine, the machine comes with certain shears. Producers should not try to adapt these shears as they become worn; this will not solve any problems, but will make problems worse by compacting the soil and your fuel consumption will increase tremendously.

- Producers should not hard face their shears. Shears need to wear; if they aren’t wearing, they’re not doing their job. By preventing the wear of the shear, you are ultimately affecting something else – be it the structure of the machine, the fuel consumption, tire maintenance or even the structure of the soil. Therefore, by solving one problem, you are actually creating ten other problems.

- Use the correct shear bolt and always make sure the shear bolts are tightened – this will affect the working of the entire machine.

- Lastly, but also very important, is the correct setting of the depth control wheels of the tillage machine as well as the setting of the tractor’s ballast.

By using your tillage machine correctly, you not only increase the longevity of the machine, you also save time and money and most importantly you can increase your yields significantly. Contact a soil scientist or an agronomist to help with advice on which implement to get and how to use it.

For more information, you can contact Pietman Botha at 082 759 2991 or Nerissa Hechter at 073 300 2068.

Publication: August 2015

Section: Focus on

Since the effect of soil preparation occurs under the soil, it is very difficult to detect faults. Normally a producer will only experience a drop in yield and not necessarily relate it to soil preparation mistakes.

Since the effect of soil preparation occurs under the soil, it is very difficult to detect faults. Normally a producer will only experience a drop in yield and not necessarily relate it to soil preparation mistakes.